Large Size Styrofoam CNC Hot Wire Cutting Machine 4 Axis with Rotary R-E2030

Suit for: Polystyrene,Foam,EPS,EVA,Cellular Glass etc

Rotary type : Vertical and horizontal type on machine table

Working size : 2000mmx3000mmx1400mm or customized as per your detailed requirements

Cutting Line: Hot Wire (1-6 pieces)

Suit for: Polystyrene,Foam,EPS,EVA,Cellular Glass etc

Rotary type : Vertical and horizontal type on machine table

Working size : 2000mmx3000mmx1400mm or customized as per your detailed requirements

Cutting Line: Hot Wire (1-6 pieces)

Large Size Styrofoam CNC Hot Wire Cutting Machine 4 Axis with Rotary R-E2030 is with large table working size 2000mmx3000mm or more bigger can be customzied as customer request. Our machine Table is separate two parts so it is easier to package and load into container for delivery.

It is a 4 axis cnc foam cutting machine with rotary two types horizontal & vertical for option that suitable for irregular products making .

And hot wire two points movement up and down, front,back separately. It is for foam regular and irregular fitures molds cutting with good quality.

It consists of a structural steel welded frame with structural steel harp carriage and wire harp.

Motion and hot wire control systems are both solid states. The motion control system includes a high-quality Four Axis Motion Controller, Stepping drives.

It also includes DXF software for simple and easy file conversion. The hot wire control system is AC powered and will Single to max six pieces wires for your option.

The machine consists of:

1). Portal Frame. It is a structural steel welded frame with structural steel harp carriage and wire harp.

2). Working table: Flat working table or similar that can fix the foam well in working and table size can be customized also.

3). Control Cabinet. It included Motion and hot wire control systems. The motion control system includes a high quality 4 Axis Motion Controller, Stepping drivers, and one Servo control system. It also includes DXF software for simple and easy file conversion.

Also have one Evoc Industrial computer with monitor for human communication and program design.

4). Transformer. It is used to heating the wire. It is a two phase AC voltage heating source. Our standard is single wires at 380/415 volts and power from 1KVA-5KVA .

5). Industry Computer that installed Mach3 software well

Foam Cutter Hot Wire Cutting machine detail specifications:

| TECHNICAL DATA |

| Model |

R-E2030 |

| X Axis Stroke |

2000mm |

| Y Axis Stroke |

3000mm |

| Max. Foam Width |

1400mm |

| Working height |

1400mm |

| Hot wire quantity |

Single wire( max 6 pieces) |

| Cutting Wire Dia. |

0.40mm |

| Control System |

Mach3 4 axis system 5 axis system |

| Program Run |

By USB |

| Cutting Speed |

0~3m/min |

| Total Power |

~800W |

| Gross Weight |

450kg |

| Overall Dimension |

2650m*1600mm*1850 mm |

| Packing size |

3650*1550*660mm |

| Unit Price |

please contact Rhino CNC sales team |

Different table size can be customized like 1300mmx3000mm/2000mmx3000mm/3000mmx4000mm etc

Machine Details as following:

1. High quality ball screw adopts for the Y axis movement to make the up and down run with high precision.

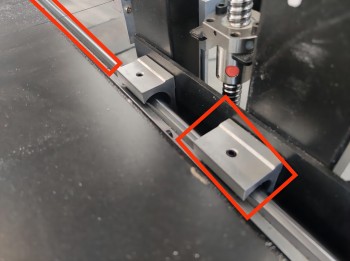

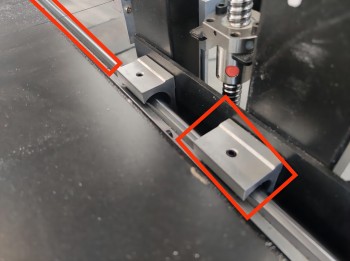

2. High Quality Liner Guider for X and Y axis

2. High Quality Liner Guider for X and Y axis ,

It is used to make the X and Y axis movement stable and reliable

3.Step Motors for X axis and Y axis Driving,There are two separate step motor for Y1 and Y2 axis driving. It can make the cutting wire not only horizontal level but also oblique.It also can be used to adjust the cutting wire water level easy.

3.Step Motors for X axis and Y axis Driving,There are two separate step motor for Y1 and Y2 axis driving. It can make the cutting wire not only horizontal level but also oblique.It also can be used to adjust the cutting wire water level easy.

4.

Cutting Wire hang and Tension

Strong spring which pulling force is 900N adopts to tension the wire to get faster cutting speed and smoother cutting surface.

In order to fix the spring well, there are many holes on the steel plate for spring hang. For the cutting wire fix, the cooper bar is made by teeth to hold the wire. There is meter on side of the teeth harp, to easy to hang the wire on same distance of two sides.

5.Control buttons

5.Control buttons

6. Rotary as optional part

Diameter 500mm-1000mm

6. Rotary as optional part

Diameter 500mm-1000mm

Firstly make design in software for this 3D foam mold, then input it into Mach3 system and put foam block on rotary and fix it well. Then the hot wire will adjust left right side and front back side level to get a perfect foam 3D mold easily !

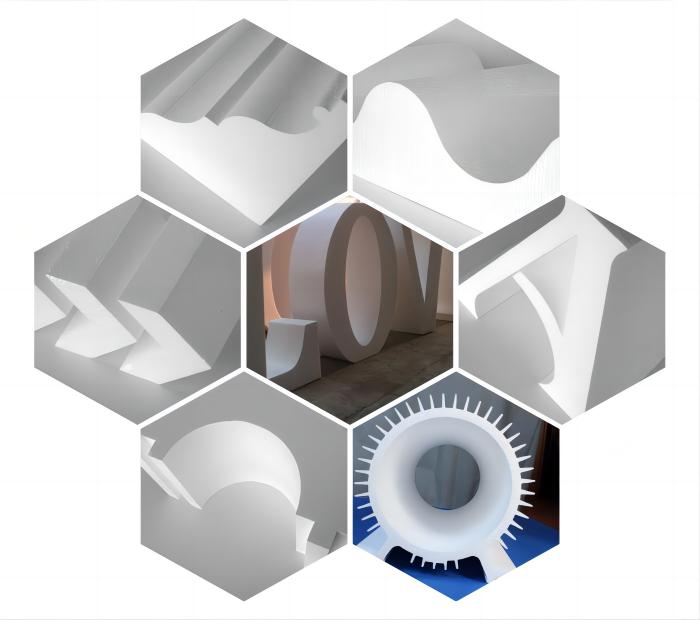

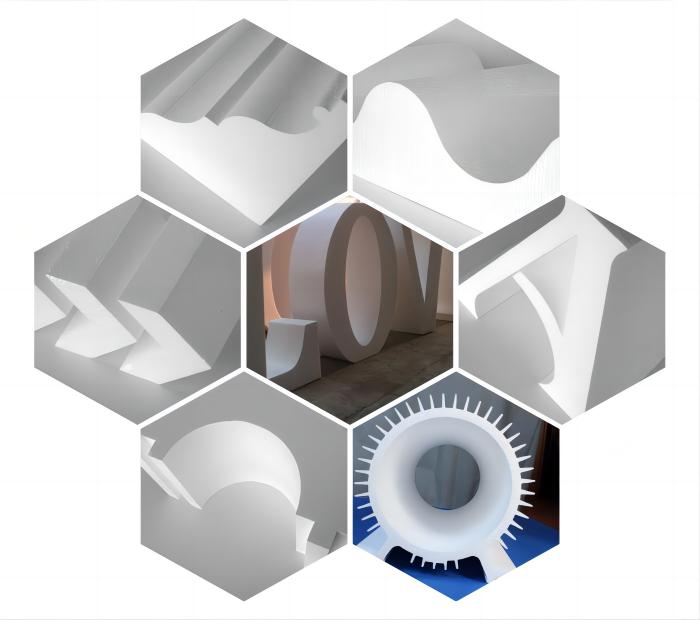

7.What our machine can cut?

If you want to learn more information about this 3D hot wire cutting machine please feel free to contact us at anytime !

FAQ:

If you want to learn more information about this 3D hot wire cutting machine please feel free to contact us at anytime !

FAQ:

1 Question: What is the maximum cutting size of this foam hot wire cutter?

Answer :The maximum cutting size of our equipment is 3m (length) × 2m (width) × 1.4m (height), which can meet most foam cutting needs. If you have greater cutting needs, we can also provide customized services.

2 Question: What is the cutting accuracy that can be achieved?

Answer : Our equipment adopts a high-precision CNC system, with a cutting accuracy of ± 0.5 millimeters, ensuring smooth cutting edges and precise dimensions.

3 Question: What types of foam materials does the device support?

Answer: Our equipment supports a variety of foam materials, including EPS, EPP, XPS, etc., and is suitable for packaging, construction, model making and other industries.

4 Question: Does the device support 3D cutting?

Answer : Yes, our equipment supports 3D cutting function, which can cut complex shapes based on the 3D model files provided by customers, making it very suitable for making sculptures, molds, etc.

5 Question: Does it support automated operations?

Answer : Our equipment is equipped with a fully automatic CNC system that supports one click start and batch production. The operation is simple and efficient, reducing manual intervention.

6 Question: Does it support importing CAD files?

Answer example: Yes, our device is compatible with multiple CAD file formats (such as DXF, STL, etc.), and you can directly import design files for cutting.

Do you want to know more about Rhino CNC?

More questions you may have welcome to contact us at anytime by mail/phone/wechat etc