There are many factors that dine ought exist addressed ago this mystery can exist properly answered. Is the machine a vertical or horizontal machine? How any axes will exist required? What is the ability of the installation turret? How are you planning above holding the part? Assuming the programmer has answered these questions because you, lets proceed. though each CNC milling machine upright will exist slightly different, these are the generic steps I follow above a daily base because a 3 axis vertical CNC milling machine.Note: I am assuming you learn some indispensable machining practices. because example, how ought utilize an margin finder, how ought navigate over your machine's control, and knowledge of indispensable CNC direct commands.

.

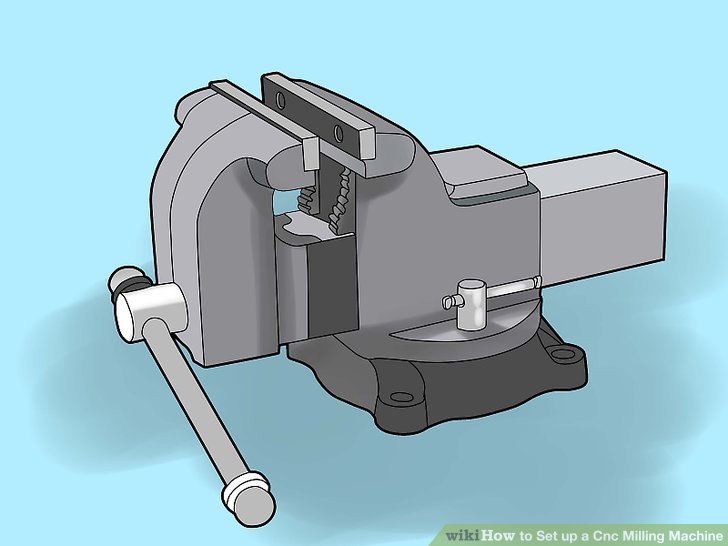

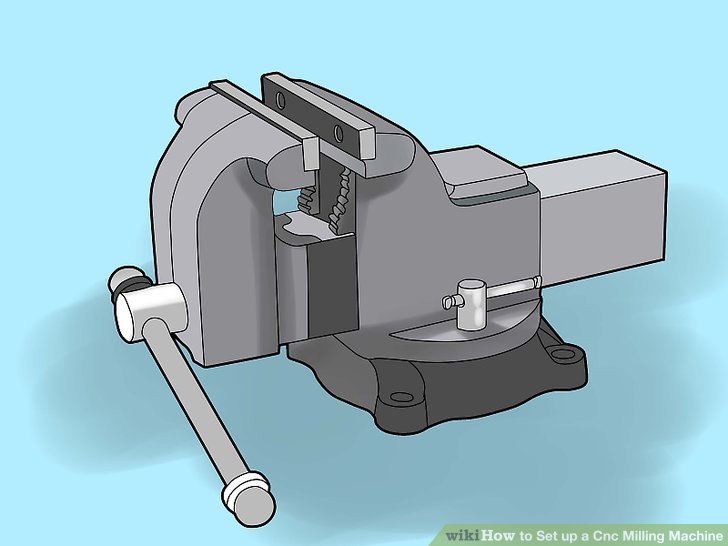

1) clean sum surfaces, because instance table, vise jaws and separate same good with a lint free cloth.

2) cargo tools needed. (including margin finder)

3) cargo separate can vise or cottage your career holding is going ought be.

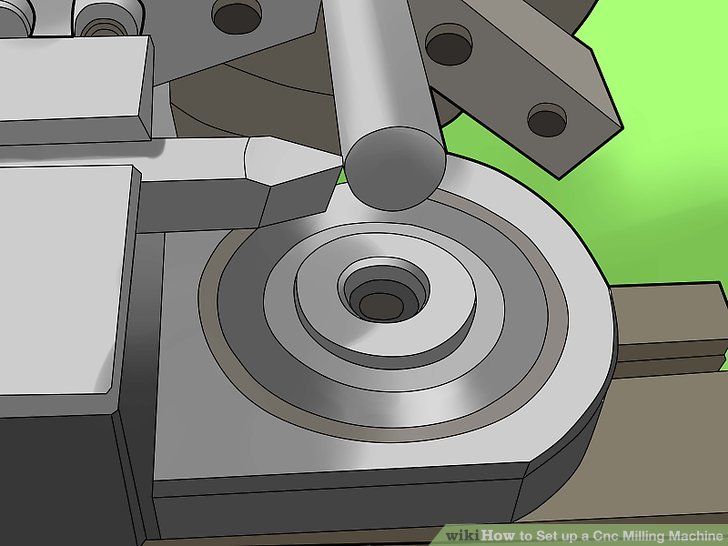

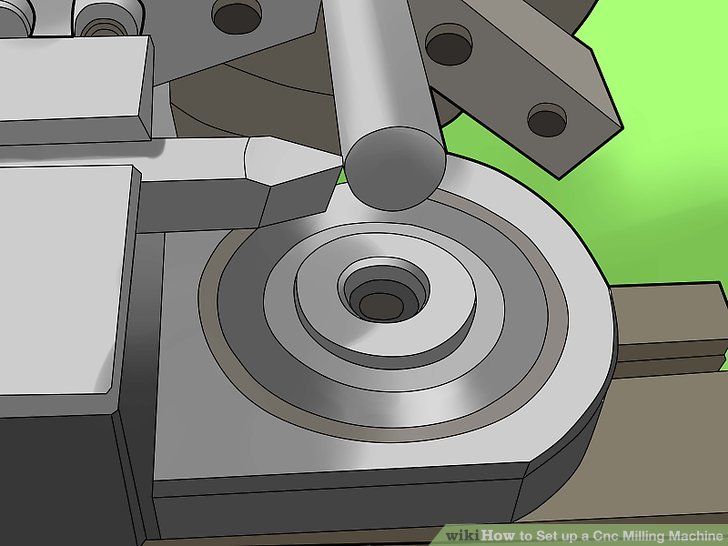

4) put career fixture offsets. create sure the machine is using the WFO that the program will exist using. if not, switch ought MDI mode, organize can G54, or G55, or G54.1P15, what ever the program will exist using. defeat Cycle Start. Using an margin finder, choice up the X0. attitude the programmer had previously established. meet can ought your WFO page and add the machines absolute X estimate ought the estimate currently can the WFO's X registry. perform the too because the Y axis.

5) put the installation length offset because each installation by loading first installation can spindle. Manually meet the Z axis down until the tool's agreement is deduce the Z0. attitude the programmer had previously established. obtain a slice of 0.001" shim stock and include it between the separate and the agreement of the tool. Carefully and lower the Z axis can 0.0001" increments until the shim stock can exist pulled with a slender drag. meet can ought your installation length offset page and enter the machine's absolute Z estimate plus -0.001 can the tools registry. cite procedure ought additional tools. Note: -0.001 is added because the shim stock's thickness.

6) Enter any diameter offsets that can absence ought exist entered if installation radius compensation will exist used can the installation offset page.

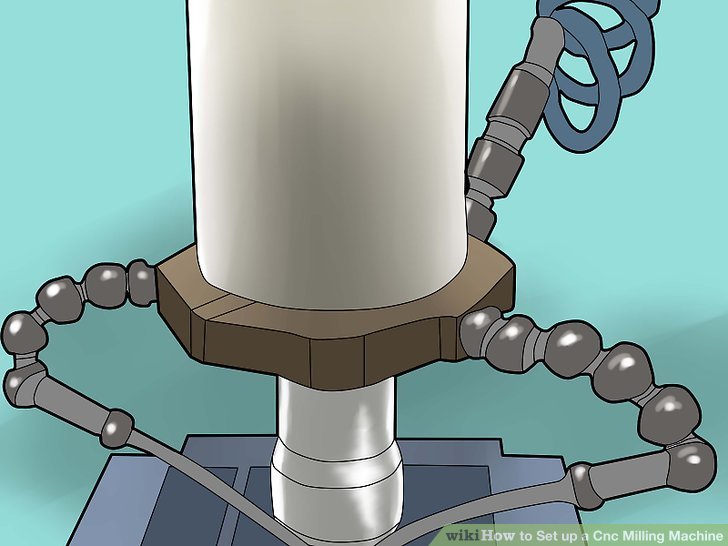

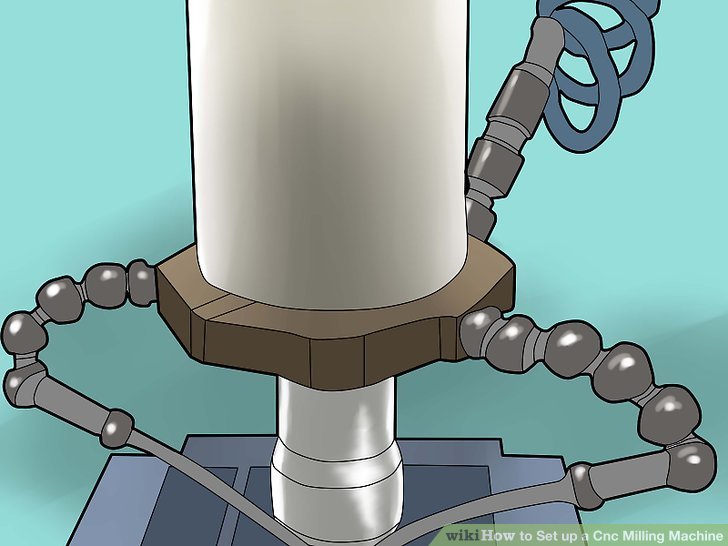

7) adapt coolant lines hence coolant can properly cold tools and wash chips away.

8) lay machine can slow rapid, only obstruction and then publication Cycle Start. exist careful and scan each obstruction programmed and watch each shift the machine makes ready ought interval the machine can example there are any programming errors. (You could also river the program 5" or whatever above the separate ought create sure each material is good and utilize Dry river if you feel it necessary.)