Rhino 1500w Fiber Laser Cleaning Machine for Metal Polishing Rust Clear Out RFC-1500W

Hand-held Fiber laser cleaning machine is with Raycus 1500w fiber source for metal surface Rust ,Painting,Oxides, Oil stains and Product Residues removing with fast speed and clearly.

It is with many good advatanges like no grinding, non-contact, and suitable for cleaning various materials

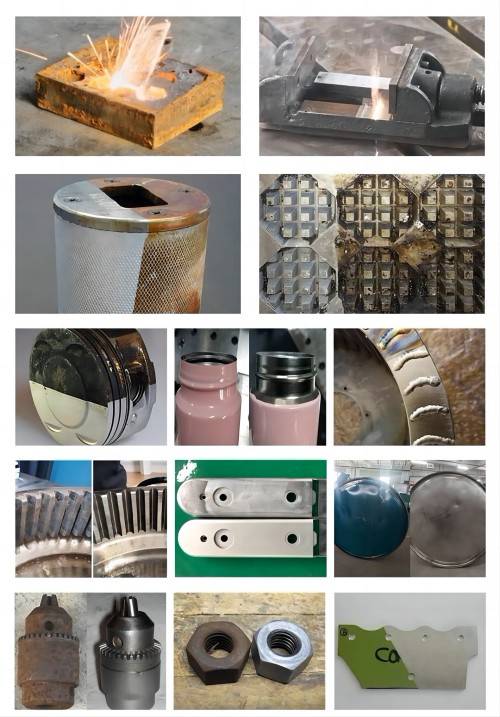

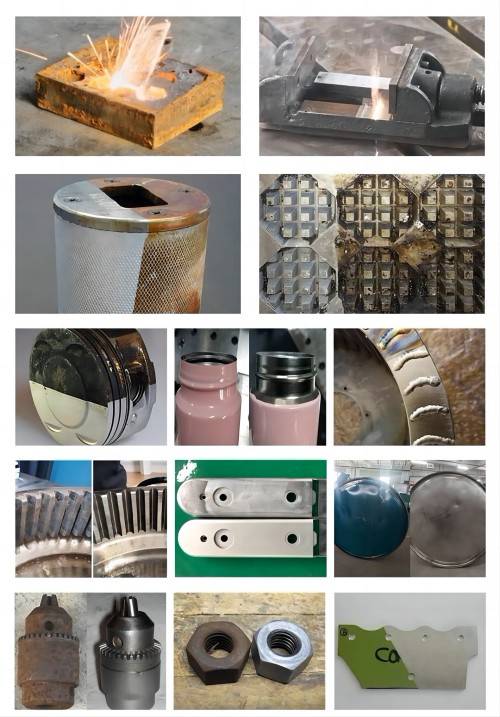

What usage of Rhino Laser Cleaning Machine ?

1. Metal or glass surface coating removal, rapid paint removal;

2. Rapid rust removal and various oxides;

3. Remove grease, resin, glue, dust, stains, and production residues;

4. Metal surface roughening;

5. Paint removal, rust removal, oil removal, oxidation, and residue treatment before welding or bonding after welding;

6. Mold cleaning, such as tire molds, electronic molds, and food molds;

7. Removal of oil stains after precision parts production and processing;

8. Rapid cleaning of nuclear power component maintenance;

9. Oxidation treatment, paint removal, and rust removal in the production or maintenance of aerospace weapons and ships;

10. Cleaning of metal surfaces in small spaces.

What Materials can be cleaned by this Fiber Laser cleaning machine ??

Metals such as steel, aluminum, copper, and titanium.

Stone materials like marble, granite, and limestone.

Plastics and composites.

Historical artifacts made of delicate materials.

Painted surfaces.

Oxides and rust on different substrates.

Application Area:

1. Mold cleaning:

Laser cleaning for tire molds can quickly recover the benefits gained from saving standby time, avoiding mold damage, ensuring work safety, and saving raw materials.

The anti stick elastic film layer on the food industry mold needs to be replaced regularly to ensure hygiene, and laser cleaning without chemical reagents is also particularly suitable for this application.

2. Cleaning of automotive components:

By using a laser cleaning system, rust and pollutants can be efficiently and quickly removed, and the cleaning area can be selected to achieve automation. By using laser cleaning, not only is the cleanliness higher than chemical cleaning technology, but it also causes almost no damage to the surface of the object.

3. Removal of old aircraft paint:

After a certain period of time, the surface of the aircraft needs to be repainted, but before painting, the original old paint needs to be completely removed. The traditional mechanical paint removal method can easily cause damage to the metal surface of aircraft, posing a hidden danger to safe flight. Laser cleaning can completely remove the paint layer on the surface of the aircraft without damaging the metal surface.

4. Cleaning in the electronic industry

The electronic industry requires high-precision decontamination, which is particularly suitable for using laser to remove oxides. Before soldering the circuit board, the pins of the components must be thoroughly oxidized to ensure optimal electrical contact, and the pins must not be damaged during the cleaning process. Laser cleaning can meet the requirements of use and has high efficiency.

| Model |

RC-2000W hand held laser cleaning machine |

| Power |

Raycus 2000W |

| Cable length |

10m/15m/20m |

| Fiber wave length |

1064μm |

| Fiber length |

10m |

| Spot size |

0.02mm |

| Working mode |

Continue |

| Laser frequency |

1-10000HZ |

| Cleaning size one time |

10-160mm |

| Location |

Red dot |

| Protective gas |

Nitrogen |

| Working speed |

0-10m/min |

| Cooling |

Industry constant temperature chiller |

| Working temperature |

15~35ºC |

| Working humidity |

<70% |

| Working voltage |

220V/380V |

| Total power |

7.5KW |

| Cable length |

10m |

| Warranty |

2 years for free and long life time service |

| Price |

FOB QINGDAO 3000-8000USD |

| Net weight |

106kg - 225kg |

| Gross weight |

138kg- 280kg |

| Package size |

2cbm |

Cleaning efficiency :

| |

Model &Power |

Cleaning width |

cleaning rust speed |

cleaning coating speed |

Gas pressure |

Voltage |

| |

Basic model 1000w |

0-200mm |

10m2/H |

5M2/H |

>= 0.5-0.8MPA |

220V 50HZ/60HZ |

| |

Standard model 1500w |

0-200mm |

20m2/H |

10M2/H |

>= 0.5-0.8MPA |

220V 50HZ/60HZ |

| |

Pro model 2000w |

0-200mm |

40M2/H |

20M2/H |

>= 0.5-0.8MPA |

220V 50HZ/60HZ |

| |

Flagship model 3000w |

0-200mm |

80M2/H |

40M2/H |

>= 0.5-0.8MPA |

220V 50HZ/60HZ |

Fiber laser source specifications:

| Max average power(w) |

200 |

300 |

| Output central wavelength(nm) |

1064±5 |

1064±5 |

| Bean quality(m²) |

≤10 |

≤10 |

| power adjustment range(%) |

10-100 |

10-100 |

| Output power instability(%) |

≤5 |

≤5 |

| Pulse repetition rate(KHZ) |

10-50 |

20-50 |

| Pulse length(ns) |

90-130 |

130-140 |

| Max pulse energy(MJ) |

10 |

12.5 |

| Fibre length(m) |

5/10 |

5/10 |

| Laser safety classification |

4 |

4 |

| cooling method Water cooling |

Water cooling |

Water cooling |

Detail photos:

Package and delivery

Rhino fiber laser cleaning Machine package process:

1. Firstly machines are inspected by engineers make sure no any problem then we have special workers who are professional for machine pacakge. We use plastic film cover machnes to avoid moisture on the sea then we use strong stap to tight machine all components well like gantry,table,dust collector and control panel etc.

2.Then we will move it on the plywood bottom bracket.

3.Setting it in the proper location then use air nail to fix machine legs well on the bracket. It will take about 1-2 hours then we make a full package with plywood box.

4.Finally we use steel strap tight the whole plywood box and print shipping mark and something else as per customer requirement on outside of box. Now the whole process is finished well and it will take 2-3 hours to package it perfectly.

About Rhino Company

About Rhino Company

Our Services(why choose Rhino cnc)

Guarantee & After Sales Service:

1) Two years warranty under machine normal use we supply maintenance for life freely.

2) 24 hours technical support by phone, email ,MSN,Skype or Remote.

3)Free training to make sure you can master the operation of machine,also we will send manual,instruction,teach video with machine together.

4)English vesion operation manual,popular and easy to understand and handle

FAQ

Q1: How can I get the best machine for me?

You can tell us your working material, detail work by picture or vedio so that we can judge whether our machine can meet your need or not. Then we can give you the best model depends on our experience.

Q2: This is the first time I use this kind of laser cleaning machine, is it easy to operate?

We will send you manual and guide vedio in English, it can teach you how to operate the machine. If you still can not learn how to use it, we can help you by "Teamviewer" online help software.Or we can talk by phone, email or other contact ways.

Q3:Is there any damage to the cleaning material?

Depends on what type you need, the pulse type has a finer cleaning effect, and the continuous type has a faster cleaning speed, Relative damage of material, pulse type is less than continuous type.

Q4:How can I test whether this machine is suitable for me?

You can tell us the material you want to clean, we will give you a test, we can give you a video call during the test so that you can see the cleaning effect more intuitively, or after the test is completed, we can send you the test video.

Q5: This model is not suitable for me, do you have more models?

Yes, we can provide a variety of models. The continuous laser cleaning machine has a trolley type; the pulse laser cleaning machine has a backpack type, a suitcase type, a trolley case type, etc. We can customize the model according to your needs.

Questions 6: What is the payment terms:

Answer: We support bank tt, LC, Western Union etc all kinds of payment way, 30% in advance and balance payment before machine delivery

Questions 7: What is the warranty time ?

Answer: Our whole machine have 3 years warranty for free and long life time service. Spindle, motor etc electronic parts have 1 years warranty for free.