750w Fiber Metal Cutting Machine with 5x10ft

750W Fiber metal Cutting Machine is mainly for all kinds of metals like stainless steel, carbon steel,aluminum, copper etc. It is used in metal industrial and crafts industry.

Main Characteristics of fiber laser cutting machine RF-1530-1000

- Superb quality of laser beam,constant BP within all the ranges of laser powers,so that long focus can still get pretty small laser spot.

- Special wavelength(1070nm), having special capability of cutting highly-reflective materials,such as aluminium, cooper and brass,etc.

- electro-optical conversion efficiency of laser supply>25%, much more efficient than CO2(<10%), so that consumption of electricity has been depleted very much.

- Laser is transmitted by fiber cables, almost no consumption during transmission.

- Modular design, “using immediately after plugging in”, mini size,easy to be installed, no maintenance of laser supply and transmission system of laser beam.

- Life span of pumping source >100,000 hours

- Precise quality of laser beam with pretty small divergence angle.

- Incomparable life span

- Using single core semiconductor pump laser supply as pump source of fiber laser supply,which has long life span. The life span of RAYCUS fiber laser supply is at least more than 100,000 hours.

- ·Lower electrical consumption, free of maintenance

- Fiber laser supply has excellent thermal properties,high efficiency, water-saving, electricity-saving, the most important point is that fiber laser supply can be used for a long time without maintenance. In that way, a lot of maintenance cost and time will be saved and working efficiency will be much improved.

- Machine working size 1500mmx3000mm and net weight 2000kg about

Suitable materials and industry application

1.Widely used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, automobile, food machinery, textile machinery, engineering machinery, precision parts, ships, metallurgy equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, and other fields.

2.Professional used to cut thin sheet metal, in a variety of high quality 0.5-10 mm carbon steel sheet cutting, also cut stainless steel plate, aluminum alloy plate, galvanized sheet, electrolytic plate, silicon steel, titanium alloy, aluminum zinc plate and other metal materials.

Machine main components

R-1530-750 Laser cutting head

1. Fiber laser cutting head,which has Z axis follow-up function. Highly sensitive and follow-up cutting head applies capacitance sensor monitoring, offering automatic adjusting function with stable and fast cutting.

2. All kinds of matching design of nozzle are applied to lens with many focuses and can also be equipped with optical lens with different focuses.

3. The focus and nozzle can be adjustable flexibly, including adjusting lens on X-Y direction and nozzles on the same axis.

Control Box

The control box of fiber laser cutting machine RF-1530-1000 is configured separately to reduce interference and easy to maintain.

To ensure the stability and avoid signal interference,we use the following measures based on electrical technology

1. The main circuit and control circuit are connected by wires separately bypass.

2. The wire of main controller use shielded or twisted wire.

3. The connection of motor and driver use separate outlet to avoid parallel with other wires.

4. I/O interface chip、controller、sensor and the connector are as close as possible.5. The connect wire between upper and lower equipment use the Aerial plug connector and Weidmuller terminal block.

Safety Protection System

1. Laser module protection

2. The laser module have warning sign to introduce the laser out avoid harm from direct laser;

3. The cover have ground connection to avoid hurt from leakage.

4. The operator need to wear suitable laser protection glasses throughout the operation;

5. Make sure the protection equipment have no wear and tear before operating;

6. Do NOT look the laser out head at any time when the device is powered; External Transmission fiber Protect section

1. The workstation of external transmission fiber ,use imported high quality guide pulley and Limit device to fix and guide laser cable;

2. The transmission fiber have protective cover made of special laser protection material to prevent the laser leak;

3. The protective cover of transmission fiber have leak sensor,if the fiber fractured to cause the laser leak,the sensor will transmit the signal to control center immediately,then the control center will stop the laser equipment and alarm.

RF-1530-750 Main Parameters:

| Model |

R--1530-750 |

| Laser type |

Fiber laser |

| Laser working medium |

Fiber |

| Laser wavelength |

1070 nm |

| Rated output power |

750W RAYCUS brand |

| Beam quality |

<0.373mrad |

| Effective cutting range |

3000×1500(mm) |

| Table axial positioning accuracy |

≤±0.03mm/m |

| Repeat positioning accuracy table |

≤±0.02mm/m |

| Cutting speed |

≤30m/min |

| Maximum table load |

1600KG |

| Power Ratings |

Three-phase AC 380V 50Hz |

| Equipment electric power |

10-20KW |

| Total power protection class |

IP54 |

RF-1530-751000 main components details:

| No. |

Item |

Brand |

Country of origin |

| 1 |

Fiber laser generator 750W |

Ray cus |

China |

| 2 |

Lubrication system |

Automatic |

China |

| 3 |

Laser head |

Ray Tools |

China(famous in laser cutting head) |

| 4 |

Reducer |

Shimpo

|

Japan |

| 5 |

Water chiller |

CWFL800 |

Wuhan,China |

| 6 |

Mechanical driving system |

High accurate bevel rack&pinion,PMI square rail |

TAIWAN |

| 7 |

High precision auto following |

Cyput |

Shanghai,China |

| 8 |

PC system |

Industrial computer |

TAIWAN |

| 9 |

X axis servo unit |

Yaskawa 850w |

Japan |

| 10 |

Y axis servo unit |

Yaskawa 850w |

Japan |

| 11 |

Z axis servo unit |

Yaskawa 400w |

Japan |

| 12 |

Reducer motor |

Shimpo |

Japan |

| 13 |

Cutting software |

Cypcut |

Shanghai,China |

| 14 |

I/O card |

Cypcut |

Shanghai,China |

| 15 |

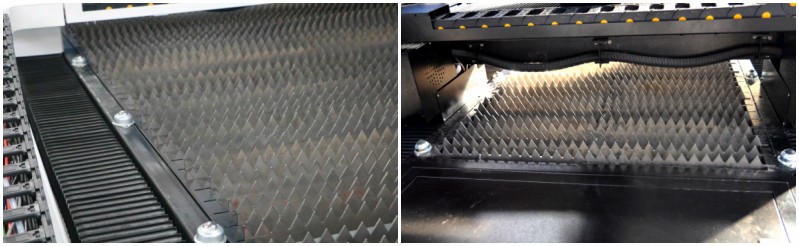

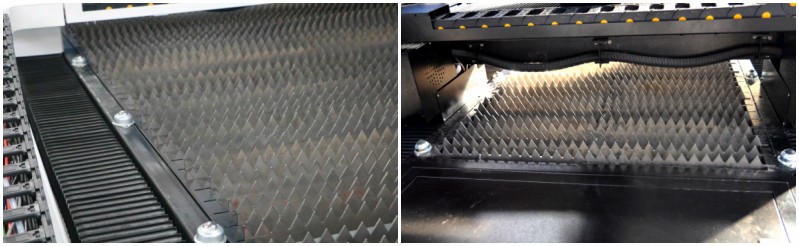

Working table |

Knife table with strictly hardening,tempering and annealing treatment,frame thickness 10mm |

Jinan,China |

| 16 |

Button module |

Schneider |

China |

| 17 |

AC Contactor |

Schneider |

China |

Different material cutting thickness list

Zincoat Sheet / SS

| Thickness(mm) |

speed(m/min) |

Pressure(Mpa) |

Gas |

Height(mm) |

| 0.5 |

17-18 |

1 |

N2 |

0.6 |

| 1 |

15-17 |

1.1 |

N2 |

0.6 |

| 2 |

4-4.5 |

1.5 |

N2 |

0.6 |

| 3 |

1.5-1.7 |

0.4 |

N2 |

0.6 |

| 4 |

0.8-0.9 |

0.15 |

N2 |

0.6 |

| |

|

|

|

|

Carbon Steel

| Thickness(mm) |

speed(m/min) |

Pressure(Mpa) |

Gas |

Height(mm) |

| 1 |

10-12 |

1 |

O2 |

1 |

| 2 |

5-6 |

0.5-0.8 |

O2 |

1 |

| 3 |

2-2.5 |

0.25-0.4 |

O2 |

1 |

| 4 |

1-2 |

0.15-0.2 |

O2 |

1 |

| 5 |

1-1.2 |

0.15-0.2 |

O2 |

1 |

| 6 |

1-0.8 |

0.1-0.15 |

O2 |

1 |

| 8 |

0.8-0.9 |

0.1-0.15 |

O2 |

1 |

| 10 |

0.6-0.65 |

0.1-0.15 |

O2 |

1 |

| |

|

|

|

|

Aluminum

| Thickness(mm) |

speed(mm/s) |

Pressure(Mpa) |

Gas |

Height(mm) |

| 1.5 |

120-130 |

1.1 |

N2/Air |

0.8 |

| 2.5 |

60-70 |

1.1 |

N2/Air |

0.8 |

| 3 |

30 |

1.1 |

N2/Air |

0.8 |

| 4 |

10 |

1.1 |

N2/Air |

0.8 |

Notes:

- The speed is for reference. The thicker, the slower

- 750w is not very perfect for aluminum cutting ,we advise you more than 1000w

Fiber cutting machine detail parts show

1. TAIWAN YYC helical rack and TAIWAN PMI square rail for transmission

2. Strong machine table that can hold thickness 12mm steel perfectly very stable

3. Japan Yaskawa servo motor drivers 850w with shimpo reducer

4. Raytool laser head 750w with fast cutting speed and high precision

5. Seperate control box with panel 6. Automatic oil box

7. Water chiller CWLF-800 S&a brand top in China 8. Remot handle with system more convenient to operate this machine

Machine cutting samples from 1mm-8mm

Machine package and delivery

Since this model RF-1530-750 package width 2.3meter we only can put it on the wooden pallet but we will tight it perfectly and fix it well inside of container so no need any worry about the transportation no matter by sea or by train.

Since this model RF-1530-750 package width 2.3meter we only can put it on the wooden pallet but we will tight it perfectly and fix it well inside of container so no need any worry about the transportation no matter by sea or by train.

FAQ

Q1,What is warranty and service you have?

A:Machine warranty 2 years for free and long life time serice and we have professional engineers who are responsible for service. We offer online/telephone/email service 7x24 hours.

We have online talking group in WhatsApp and Wechat with engineers and customers

Q2,How can I confirm machine specifications?

A:Firstly we need to know the working size you need and what is materials you want to cut also if you have your own requirements let me know at anytime please

Q3,What is software of machine you use?

A:We use Cypuc standard version that professional for thick metal cutting solution perfectly

Q4,Do you offer training for the softwares?

A:Yes, we have engineer who work this two softwares so you can come our factory or we send them to your company to give you training

Q5,Could you customized this fiber laser cutting machine as per our detail requirement?

A:Yes, you give us all your detail requests and we make agreement then start machine productime

We have two workshops one for cnc router production and another for laser cutting machine production.

Every month export more than 100 machines to different countries like India.Thailand,Europe and America etc

Now we are looking for more agents in whole world and win-win together in globe market.