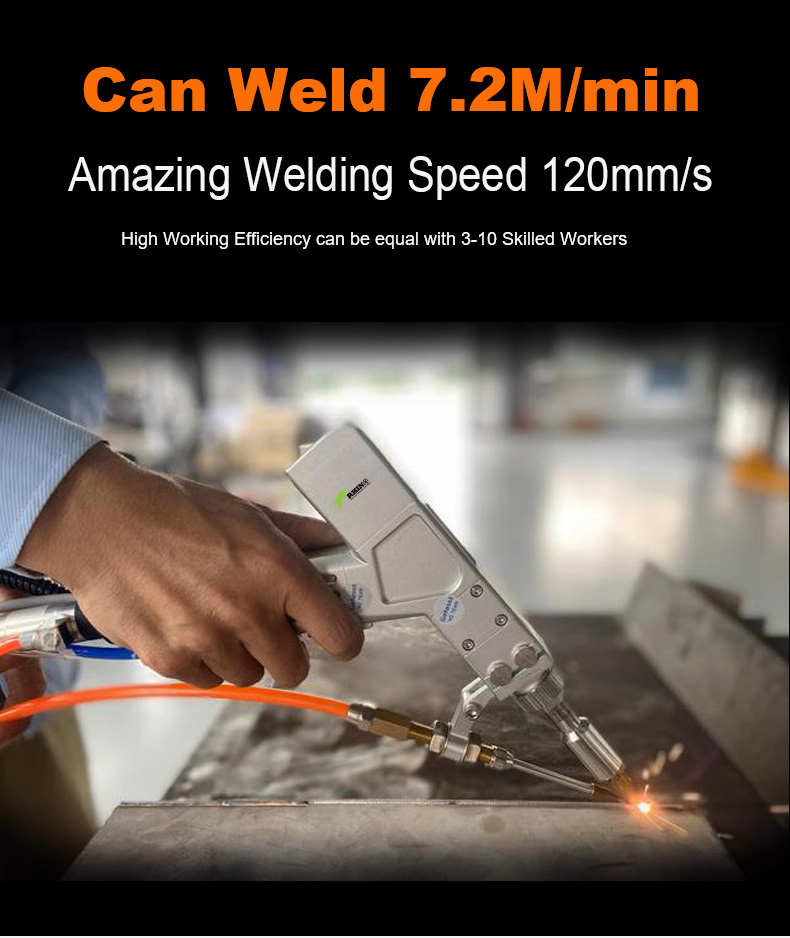

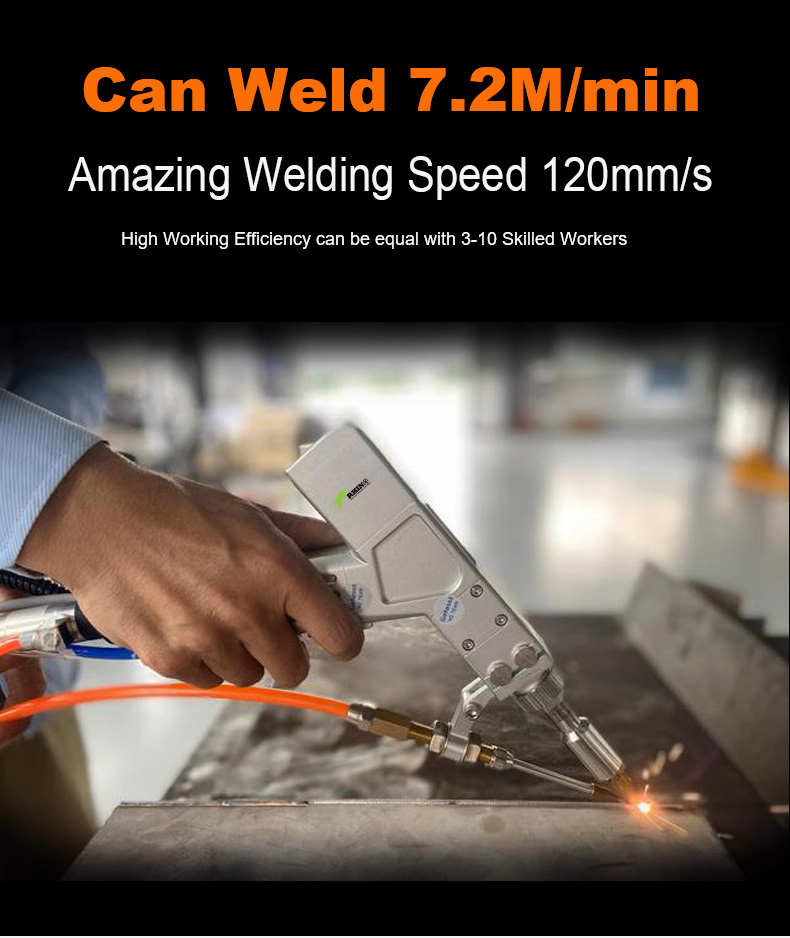

Rhino Raycus 2000w Hand-Held Metal Fiber Laser Welding Machine Laser Welder RFW-2000

This is Rhino new technology

handheld fiber laser welding machine,that uses fiber laser to weld metal materials.

Commonly used for manufacturing industrial products such as automotive, aircraft, and electronic components.

It can weld metal materials and complete the work in a very short time.

There have 1000w/1500w/2000w/3000w for option .

Also laser cleaning and laser cutting function can be added by this machine.

More details welcome to contact RhinoCNC at anytime !

What usage of Rhino hand held fiber Laser welding Machine ?

1、 Welding

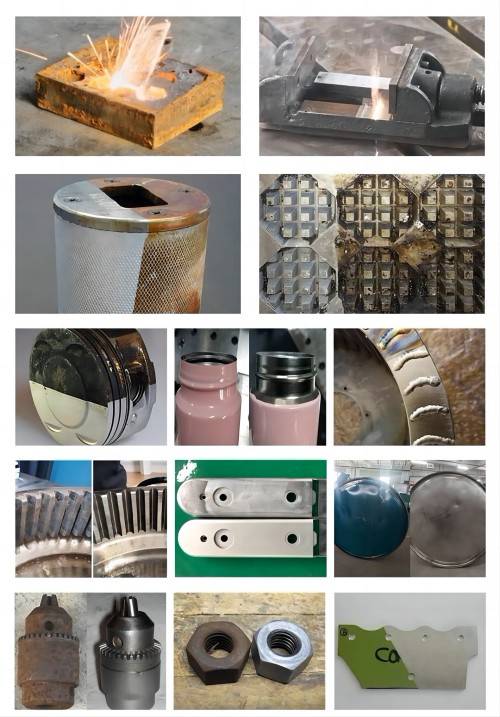

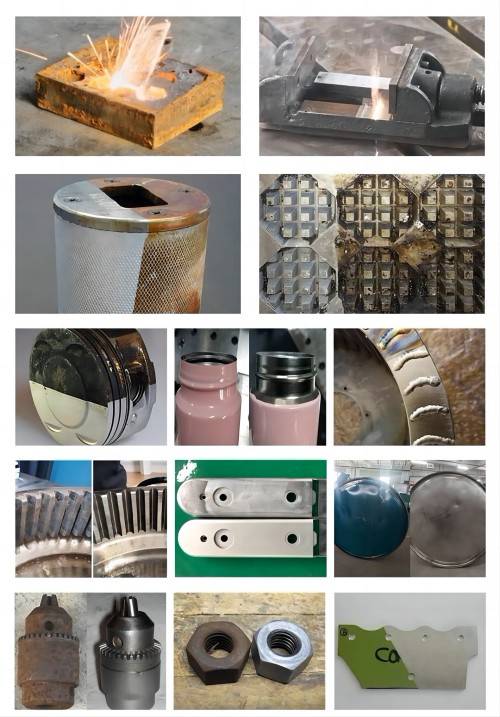

The main purpose of laser welding machines is undoubtedly welding. They can not only weld thin-walled metal materials such as stainless steel plates, aluminum plates, galvanized plates, but also be used for welding sheet metal parts, such as kitchen utensils.

They are suitable for welding their flat, straight, arc, and any shape, and are widely used in precision machinery, jewelry, electronic components, batteries, clocks, communication, handicrafts and other industries.

They can complete welding well in various complex environments, with high production efficiency and more obvious advantages than traditional argon arc welding, electric welding and other processes.

Using a laser welding machine, the welding seam width is small, the depth is large, the thermal shock area is small, the deformation is small, the welding seam is smooth and beautiful, the welding quality is high, there are no pores, it can be accurately controlled, the welding quality is stable, and there is no need for treatment or simple treatment after welding.

2、 Repair

The purpose of hand Held laser welding machines is not only for welding, but also for repairing defects such as wear, defects, scratches on molds, as well as sand holes, cracks, and deformations in metal workpieces.

If the mold is used for a long time, it will wear out. If it is directly discarded, the loss will be significant. The problematic mold can be fully utilized again through repair using a laser welding machine, especially when repairing fine surfaces. This avoids the two processes of thermal strain and post weld treatment, greatly saving production time and costs.

3、 Cutting

Laser cutting is a new cutting method that uses laser welding machines to cut materials such as stainless steel, copper, aluminum, zirconium, and their alloys. In addition, it can also cut non-metallic materials such as plastics, rubber, wood, etc.

What Materials can be cleaned by this Fiber Laser cleaning machine ??

Metals such as steel, aluminum, copper, and titanium.

Stone materials like marble, granite, and limestone.

Plastics and composites.

Historical artifacts made of delicate materials.

Painted surfaces.

Oxides and rust on different substrates.

Application Area:

Widely used in the Aerospace industry,

Automotive manufacturing,

Electronic manufacturing,

Kitchen and Bathroom industry,

Home appliance industry,

Advertising industry,

Mold industry,

Stainless steel product industry,

Stainless steel engineering industry,

Door and window industry,

Handicraft industry,

Household goods industry,

Furniture industry,

Automotive parts industry, etc

Handheld Fiber Laser Welding Machine Features:

- High laser energy density, small thermal effect area, not easy deformation, less or no subsequent processing.

- Top brand gold cavity, high temperature resistance, corrosion resistance, the service life is 8 to10 years, the xenon lamp service life is more than 800 million times

- Easy spot welding, stack welding, splicing and continuous welding.

- Variety of detection and protection measures using, greatly avoid the faults caused by a variety of external factors or human misuse, to protect the equipment with long-term stable operation.

- Non-contact processing, stress free, noiseless, no pollution to the environment,Good welding quality, smooth and beautiful appearance.

6. The communication function monitors all data of the laser.

7. It adopts a specific fiber to achieve the welding of tiny solder bumps.

8. High quality fiber laser beam, high conversion efficiency and high welding speed, high aspect ratio, high strength.

9. Excellent spectral system minimizes energy loss to ensure that the laser energy of each fiber is almost the same.

Specification:

| Machine Name |

Hand-held Fiber Laser Welding Machine RW-2000 |

| Laser Power |

2000W RAYCUS |

| Laser Wave Length |

1080nm |

| Laser Source |

Raycus 2KW with auto feeding |

| Fiber Length |

10M |

| Cooling Mode |

Water cooling |

| Laser Pulse Frequency |

1-20HZ |

| Pulse Width |

0.1-20ms |

| Adjusted spot range |

0.1-3mm |

| Minimum Welding pool |

0.1mm |

| Welding efficiency |

150m3/H |

| Gas source |

0.2Mpa (Argon ) |

| Working Voltage |

AC220V / 50Hz / 60HZ |

| Gross Weight |

330KG |

| Application |

This series laser welding machine is perforation, widely used in kitchen industrial , household appliances , advertisement , module industrial , stainless windows and doors , handiwork , home supplies, automobile spare parts industry . |

| Price |

Please contact our sales team |

Fiber laser source specifications:

| Max average power(w) |

200 |

300 |

| Output central wavelength(nm) |

1064±5 |

1064±5 |

| Bean quality(m²) |

≤10 |

≤10 |

| power adjustment range(%) |

10-100 |

10-100 |

| Output power instability(%) |

≤5 |

≤5 |

| Pulse repetition rate(KHZ) |

10-50 |

20-50 |

| Pulse length(ns) |

90-130 |

130-140 |

| Max pulse energy(MJ) |

10 |

12.5 |

| Fibre length(m) |

5/10 |

5/10 |

| Laser safety classification |

4 |

4 |

| cooling method Water cooling |

Water cooling |

Water cooling |

Also can be have Cleaning Function !

Also can be have Cleaning Function !

Detail photos:

Package and delivery

Rhino fiber laser cleaning Machine package process:

1. Firstly machines are inspected by engineers make sure no any problem then we have special workers who are professional for machine pacakge. We use plastic film cover machnes to avoid moisture on the sea then we use strong stap to tight machine all components well like gantry,table,dust collector and control panel etc.

2.Then we will move it on the plywood bottom bracket.

3.Setting it in the proper location then use air nail to fix machine legs well on the bracket. It will take about 1-2 hours then we make a full package with plywood box.

4.Finally we use steel strap tight the whole plywood box and print shipping mark and something else as per customer requirement on outside of box. Now the whole process is finished well and it will take 2-3 hours to package it perfectly.

About Rhino Company

About Rhino Company

Our Services(why choose Rhino cnc)

Guarantee & After Sales Service:

1) Two years warranty under machine normal use we supply maintenance for life freely.

2) 24 hours technical support by phone, email ,MSN,Skype or Remote.

3)Free training to make sure you can master the operation of machine,also we will send manual,instruction,teach video with machine together.

4)English vesion operation manual,popular and easy to understand and handle

FAQ

1. The state of the laser head is not displayed:

X.Y motor cable is loose, or 15V power input is interrupted, or the motor is damaged.

2. No on state display or intermittent light output during welding:

it may be that the communication signal is not connected or the wire is loose and not plugged tightly, and the crocodile clamp does not form a loop with the X5 signal.Intermittent light may be due to the shaking of the nozzle during the welding process, or the plate rusted, not connected with the clamp.

3. The status of the welding torch is not displayed:

it may be that the switch button of the welding torch tip is loose, the terminals are loose or the interface is unwelded.

4. Uncontrollable gas:

the gas button on the touch screen is not closed, or the gas delay is set too high, or the positive and negative terminals of the air valve are connected in reverse.

5. The parameters of the handheld head LCD screen and the setting parameters of the touch screen are out of sync:

the power supply input of the system 24V and the power supply input of the galvanometer 15V cannot be powered on at the same time, resulting in out-of-sync parameters and unable to update data.

6. Easy to burn the protective lens:

the gas is not pure or no air pressure, the working environment is bad, the focus is off, the water cooling system is damaged, and other factors.During welding, the start and end delay of gas is set at about 150ms, and the focus position should be slightly off the positive focus, welding at about 2MM of negative defocus.

7. Overheat of welding torch head:

the protective lens burns or the water circulation of chiller

fails to pass or is caused by water fault.