Stone CNC Carving Machine for Marble Granite with Rotary

This is our stone cnc carving machine that professional for marble granite pvc wood glass metal etc hard materials cutting

and engraving both no problem. It is with rotary attachment that work for 3D perfectly.

Working materials by stone cnc carving machine R-1325Y:

This machine can work all kinds of materials like marble,granite,glass,metal,aluminum,steel,plastic,wood,pvc,acrylic,solid wood etc hard materials no problem.

How to find a good quality stone cnc carving machine

1. First of all, we need to determine the overall dimensions and engraving dimensions of the machine, including length, width and height. If it is a multi head engraving machine, we need to focus on the engraving dimensions of each head when the multi head is working and the engraving dimensions when the single head is working.

2. The underframe of the machine, also known as "shelf", mainly refers to the size, specification and classification of the underframe. which is the platform of the whole machine.

3. Cross beam, supporting and fixing the moving parts of x-axis and z-axis.

4. The machine head:machine are working through the head movement.

5. Precision machining of machine:means the parts which need to be processed with high precision. For example, lathe, milling machine, drilling machine, planer, double arm planer, machining center, etc.

6. Heat treatment:machine underframe, gantry, head components, etc. if they are not treated after welding, the machine will deform with time, and the longer the time is, the larger the deformation will be. Heat treatment process is to eliminate and reduce this deformation.

7. Water tank.:The machine uses circulating water to spray water for tools cooling. The water tank is the place where water is stored. Rhino company use stainless steel material water tank in machine.

8. Table:it is the place where stone workpieces are placed on the machine. There are many kinds of designs for the table top, such as soft PVC on the aluminum profile plate, super hard polyester plate inlaid with aluminum profile strip, super hard polyester plate fixed on the channel steel table top, and super hard polyester plate fixed on the hollow table top, etc. Channel steel table and hollow table are convenient for machine tool cleaning, which is Rhino cnc company used in this stone cnc carving machine.

9. The common materials of the platform panel are soft PVC and super hard polyester board. Soft PVC is easy to be damaged, which affects the processing flatness. we use super hard polyester board.

10. Control card, which is the brain of the whole stone carving machine, reads the analysis programming file and outputs the processing signal. All the movements on the machine tool originate from the signals output by the control card.

Features of Stone cnc carving machine R-1325Y

1. Optimize technology of frequency conversion to save 10 kilowatt hours per day.

2. The carving depth of one layer is up to 15 cm, and the speed is increased by 100 times.

3. Simple operation makes carving easier.

4. Automatic leveling, uneven stone can be engraved with flat words.

5. Special spindle which can work on all kinds of materials like hard stone, glass, metal etc

6. Strong power and precision. 5-year warranty, lifetime after-sale.

7. Professional waterproof treatment, so that the service life of the machine is more than 20 years.

8. Stainless steel water retaining treatment to protect the gantry beam of the equipment no damage.

9. The bed bears 10 tons, making the carving easier. Optional automatic feeding function

10. Stainless steel water tank is used as a whole.

11. It can achieve progressive carving (for double head carving machine, it can carve one pair at a time)

12. Add spindle temperature monitor. (the reserved interface for automatic shutdown after reaching the temperature is optional)

Technical specifications of stone cnc carving machine :

| Stone Series CNC Router R-1325Y |

| Items |

Parameters |

| Working area(mm) |

X |

1300 |

| |

Y |

2500 |

| |

Z |

400 |

| Table Structure |

Table Surface |

water sink+T-slot with Polyester covers |

| INVERTER |

BEST 5.5KW |

Good brand from China |

| Transmission system |

X |

Gear Rack from Taiwan |

| |

Y |

Gear Rack from Taiwan |

| |

Z |

Ballscrew from Taiwan but with German technology |

| Lead rail system |

X |

HIWIN Square guide rail from TAIWAN |

| |

Y |

HIWIN Square guide rail from TAIWAN |

| |

Z |

HIWIN Square guide rail from TAIWAN |

| Spindle |

Power |

6kw |

| |

Rotating Speed |

0-24000 rpm |

| |

Cooling Type |

Water-cooling |

| |

Origin |

China CHANGSHENG brand |

| |

Collect diameter |

3/4/6/8/12.7mm |

| |

Auto tool zero |

YES |

| About drive systems |

X |

DELTA 750W Servo motor |

| |

Y |

DELTA 750W Servo motor |

| |

Z |

DELTA 750W Servo motor |

| |

motor and driver |

From China |

| Machine body |

Whole cast iron/inblock cast |

| Software environment |

Windows 98/2000/XP/windows 7 |

| Control System |

DSP system |

| Data reading mode |

line by line |

| Compatible file formats |

G code ; *.u00 ; *.mmg ; *.plt . |

| Working Voltage |

AC380V 50Hz/60hz 3 phase |

| Table size |

1380*2550mm |

| Precision |

0.005mm |

| Max speed |

30m/min |

| Max engraving speed |

30m/min |

| Max feeding height |

400mm |

| Rotary attachment |

Diameter 200mm with length 2500mm |

| Payment terms |

30% t/t in advance and 70% t/t before machine delivery |

| Delivery time |

5-7 working days |

| Warranty guarantee |

One-year after-sale services |

| The above parameters are subject to change without prior notice. |

Detail components of stone carving machine

1. Strong machine table with 5 wheels easy to load materials

1. Strong machine table with 5 wheels easy to load materials

2.Rotary attachment as 4 axis that can engrave 3D products 3.Professional stone working water cooling spindle 6kw with 4 bearings inside

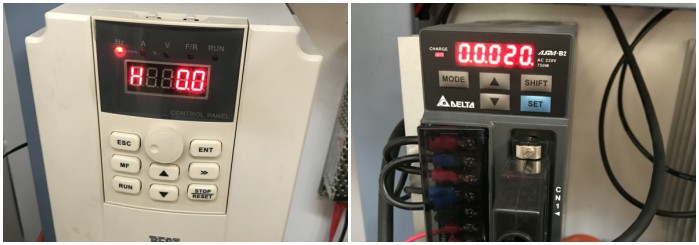

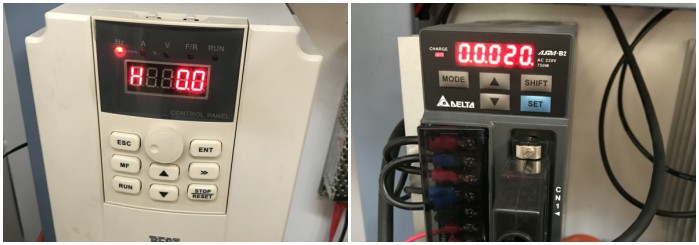

4. BEST inveter that with 8 degrees to control speed 5. Taiwan Delta servo motor and drivers 750W

6. New type clampls simple to operate and stronger than old ones

Carving flat and rotary samples:

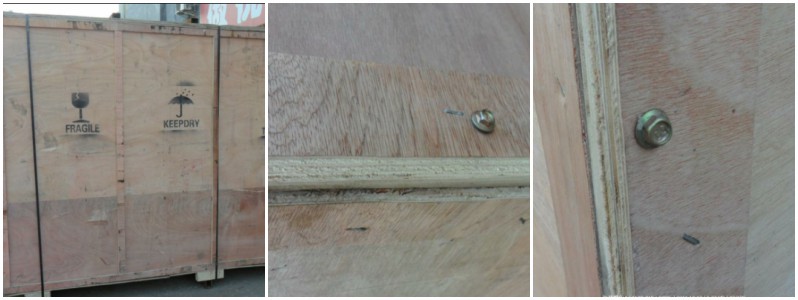

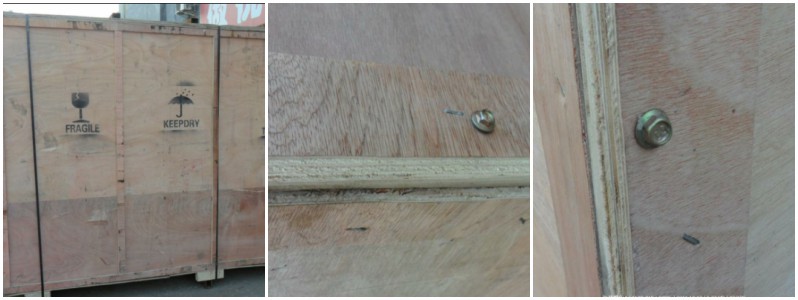

How we pacakge this machine ?

Rhino CNC Machine package process: Firstly machines are inspected by engineers make sure no any problem then we have special workers who are professional for machine pacakge. We use plastic film cover machnes to avoid moisture on the sea then we use strong stap to tight machine all components well like gantry,table,dust collector and control panel etc. Then we will move it on the plywood bottom bracket. Setting it in the proper location then use air nail to fix machine legs well on the bracket. It will take about 1-2 hours then we make a full package with plywood box. Finally we use steel strap tight the whole plywood box and print shipping mark and something else as per customer requirement on outside of box. Now the whole process is finished well and it will take 2-3 hours to package it perfectly.

Welcome to send your inquiry to us by mail at anytime please!

Welcome to send your inquiry to us by mail at anytime please!