ATC Wood CNC Machine with linear tool changer maganize for sale

ATC WOOD CNC Machine is a good machine for furnitures making with automatic tool changer function so that improve efferency.

This ATC CNC router machine also with perfect dust adsorb system that keep a more clean working environment.

Advantages of Best CNC Router RSKM25-E:

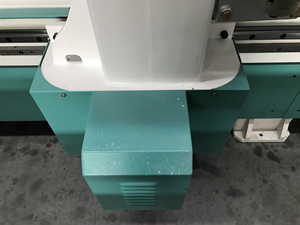

1. This machine is with perfect dust system behind of gantry with device to collect all dust

2. Machine is with pneumatic linear tool changer function to save time of different tools swifting.

3. Safe operation system and all cables plugs are under European standard

4. Fast cutting speed could be 40m/min and travel speed can be 50m/min

5. Disc automatic tool changer magazine 8 pcs that can switch 1-2 seconds very fast

6. For wood carving precision could be 0.05mm perfectly

7. Automatic height adjust legs,if your ground is not flat machine can be adjusted itself well

8. Whole dust proof system with pipe 30mm diameter to help you keep a more clean working environment

9. Different tools switch fastly can be within 1-2 seconds

10. Fast service support, if you have any doubts for this machine in operation we give you 7x24 hours fast reply at anytime

The Application of CNC Router Machine RSKM25-G

1. Furniture: all kinds of furnitures like cabinet,door,windows,beds etc

2. Office furnitures:Table, chair, sofa, stands etc

3. Sign: LED light,bending letters,pvc cutting,acrylic cutting,sign letters etc

4. Mould marking:wood mould,shoes mould,aluminum mould,tooth mould etc

The Detail Accessories of ATC Wood CNC Router RSKM25-G:

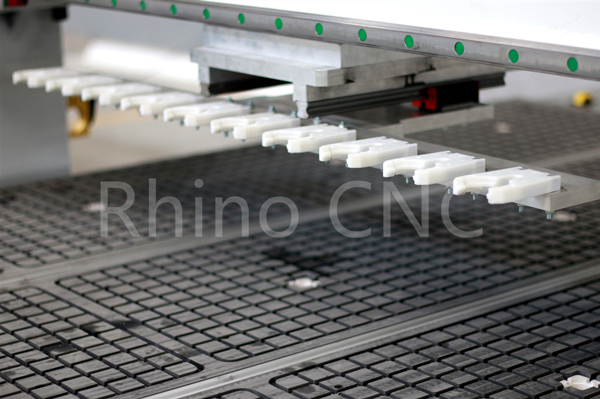

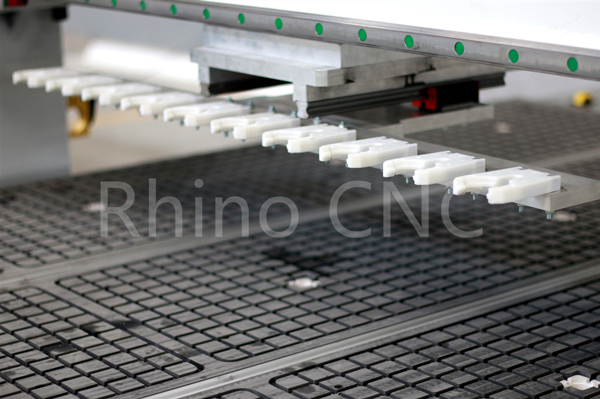

1. Tool magazine:Our machine have two typles one is disc tool changer magazine can hold tool holder 6-20 pcs and another typle linear tool changer also can hold tool holders 6-20pcs no problem.

2. Perfect dust system: Behind of gantry we install a special device to collect all dust into dust brush more easily

3. Pneumatic liear tool magazine: It is controlled by forth axis from system so can shorten the time of tool chaning then improve working efficiency

4. Working transmission:HIWIN25 or HIWIN30 oringla linear rails from Taiwan for XYZ axis and Helica rack pinion also from Taiwan

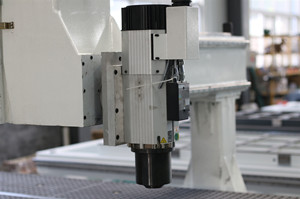

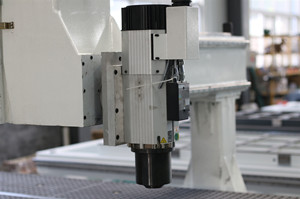

5. Spindle motor :HQD 9KW ATC spindle with machine with 24 month service for free

6. Motors and drivers:Yaksawa servo motor drivers 850w from Japan Original

7. Control system: Syntec 6MB system latest version with keyboard and screen whole set max support 4 axis

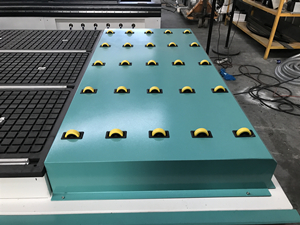

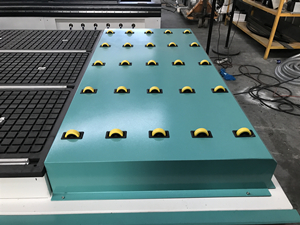

8. Machine working table:Vacuum table with toughness pvc materials with drawing 8 zones. T-SLOT combination also no problem

9. Cables :We use Germany quality strong cable inside 6 lines make sure many years working no problem

10 Dust collector with pipes:We use dust pipr diameter 30mm and dust brush two holes can working together.Dust device can collect dust and together adsorbded to dust collector well.

11. Vacuum pump:5.5kw or 7.5kw vacuum pump air cooling tyle with noise reducer to make sure low noise

ATC Wood Cnc machine detail parameters:

| Number |

Description |

Parameter |

| 1 |

X,Y,Z Working Area |

1300mmx2500mmx200mm/1500MMX3000MM for your option |

| 2 |

Table Size |

1330mm×3140mm |

| 3 |

X,Y,Z Traveling Positioning Accuracy |

±0.03/300 |

| 4 |

X,Y,Z Repositioning Accuracy |

±0.03mm |

| 5 |

Table Surface |

Vacuum and T-slot Combined (Option: T-slot table) |

| 6 |

Frame |

Welded structure |

| 7 |

X, Y Structure |

Rack and Pinion Drive, Hiwin Rail Linear Bearings |

| 8 |

Z Structure |

Hiwin Rail Linear Bearings and Ball Screw |

| 9 |

Automatic tool changer |

Linear type(disc type for option) |

| 10 |

Pieces of tool changer |

10 pieces |

| 11 |

Max. Working Speed |

40000mm/min |

| 12 |

Spindle Power |

ATC 9.0 kw |

| 13 |

Spindle Speed |

0-24000RPM |

| 14 |

Drive Motors |

Yaskawa servo motor 850W |

| 15 |

Working Voltage |

AC 380V/50/60Hz,3PH |

| 16 |

Command Language |

G Code |

| 17 |

Operating System |

Syntec Control System |

| 18 |

Computer Interface |

Ethernet, CF Card |

| 19 |

Flash Memory |

512M(U Disk) |

| 20 |

Collet |

ER32 |

| 21 |

X,Y Resolution |

<0.03mm |

| 22 |

Software Compatibility |

Type3/UcancameV9 software |

| 23 |

Running Environment Temperature |

0 - 45 Centigrade |

| 24 |

Relative Humidity |

30% - 75% |

| 25 |

Packing Size |

3500X2250X2200mm |

| 26 |

N.W. |

1800KG |

| 27 |

G.W. |

2000KG |

| 28 |

Delivery time |

14-20 working days |

Optional parts of Best CNC Router machine RSKM25-G we offer:

| Part |

Brand |

| ATC spindle mtor |

we have economic China made ATC spindleHQD brand |

| Servo motor drivers |

Leashine servo/delta servo/Panasonic servo/syntec servo etc |

| Control ststem |

OSAI/WEIHONG/MACH3/DSP etc |

| Linear rails |

PMI brand |

| Limit sensor |

OMRON brand |

| Vacuum pump |

TongYong brand from germany for your option |

ATC wood router machine detial components:

1. Good dust collection system behind of gantry

1. Good dust collection system behind of gantry

2. Automatic tool sensor device

2. Automatic tool sensor device

3. Syntec control system 6MB that work 4 axis no problem

3. Syntec control system 6MB that work 4 axis no problem

4.Spray oil cooling for tools is available for aluminum milling and cutting

4.Spray oil cooling for tools is available for aluminum milling and cutting

4. Linear tool changer 10 pcs (8pcs)

4. Linear tool changer 10 pcs (8pcs)

5. Electronic parts with Yaskawa servo motor drivers 850w and Delta servo VFD

5. Electronic parts with Yaskawa servo motor drivers 850w and Delta servo VFD

6. ATC spindle 9kw air cooling spindle ISO30 tool holder

6. ATC spindle 9kw air cooling spindle ISO30 tool holder

7. Wheels behind of table 8.Strong machine gantry with new color as per customer requirement

7. Wheels behind of table 8.Strong machine gantry with new color as per customer requirement

Cutting samples of ATC Wood CNC Router RSKM25-A

FAQ of Rhino ATC CNC Router machine:

1. How long time warranty and service

A: Whole machines 2 years warranty for free and long life time service ?

2. How long time warranty of spindle?

A: Spindle motor and other electronic parts 12 month warranty for free

3. Do you have online service?

A: Online training and videos are available

4. What will you do after sold machine to me?

A: We have report for every machine sold out so we would like to receive your feedback for every machines after run it

5. If I need engineers to my company can you send it?

A: We have engineers with passport so can go your company to give you training face to face

6. Can I contact your engineer online directly?

A: Yes, Egnineer group with every customers you can contact with our engineers directly online

7. What is time we can contact you

A: 7x24 hours service is available

Production process of CNC Router Machine RSKM25-E:

⇒

⇒

Step 1. Machine structure welding and milling by CNC center high accurate

Step 2. After milling table then two times painting color as per customer color

Step 3. It need 5-7 working days to install this machiine by our workers

Step 4. It will take 1 day by our engineer to inspect this machine after that this machine is finished completely

WELCOME TO CONTACT US BY MAIL OR PHONE AND WE WOULD LIKE TO OFFER YOU THE BEST SOLUTION !

⇒

⇒