Z axis 500mm CNC Router CNC Engraving machine for Foam MDF Plywood

This CNC Router CNC Engraving machine with z axis 500mm height is professional for wood foam,PE,EPS ets

hard materials cutting milling drilling that can make different products like moulds of boat, cars, furnitures etc.

Advantages of CNC Router cnc engraving machine R-1530H

1. Machine z axis height is 500mm means the max feeding height could be 500mm no problem. also we can custom z axis max 1500mm

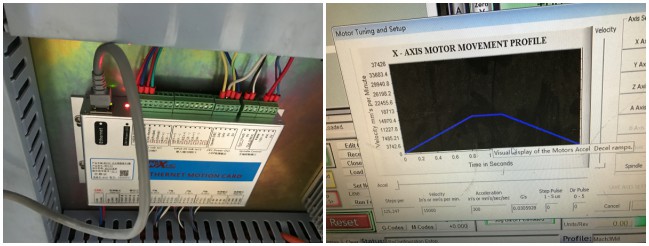

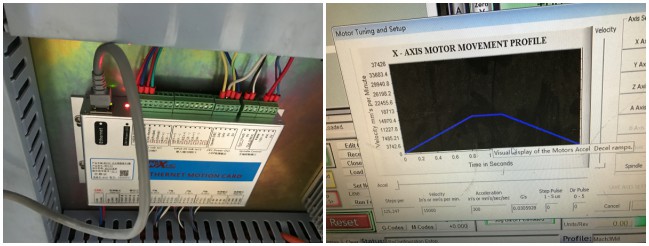

2. Friendly MACH3 control system with ethernet connection easy to learn and opereate

3. This machine is with perfect dust system behind of gantry with device to collect all dust

4. Machine gantry beam is whole cast iron stronger than other models

5. Safe operation system and all cables plugs are under European standard

6. Fast cutting speed could be 40m/min and travel speed can be 50m/min

7. Different designs softwares we offer like Artcam/type3/ucancam V11 can install into computer 32bit 64bit both no problem

8. For wood carving precision could be 0.05mm perfectly

9. Automatic height adjust legs,if your ground is not flat machine can be adjusted itself well

10. Whole dust proof system with pipe 30mm diameter to help you keep a more clean working environment

11. Servo motor and driver system to make sure molding making much better precision

12. Fast service support, if you have any doubts for this machine in operation we give you 7x24 hours fast reply at anytime

The Application of CNC Router cnc engraving machine

1. Mould marking:wood mould,shoes mould,aluminum mould,tooth mould engraving and cutting

2. Furniture: all kinds of furnitures like cabinet,door,windows,beds etc

3. Office furnitures:Table, chair, sofa, stands etc

4. Sign: LED light,bending letters,pvc cutting,acrylic cutting,sign letters etc

The Detail Accessories of cnc router cnc engraving machine R-1530H

1. Machine structure and gantry beam: we use rigid steel heavy duty tubes for machine structure and gantry to make sure z axis height 500mm in working perfectly and stable well

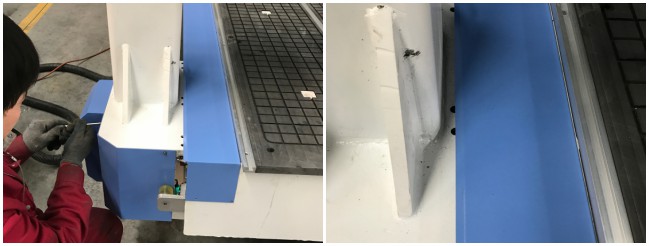

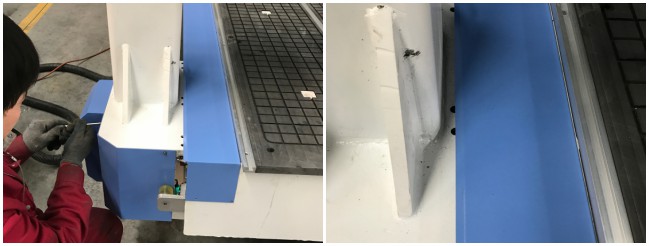

2. Perfect dust system: Behind of gantry we install a special device to collect all dust into dust brush more easily

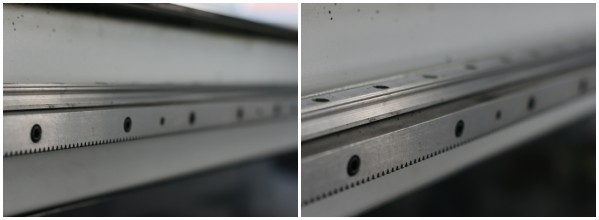

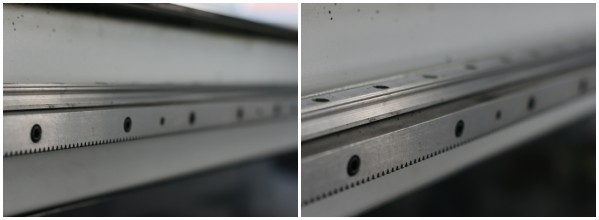

3. Working transmission:HIWIN25 or HIWIN30 oringla linear rails from Taiwan for XYZ axis and Helica rack pinion also from Taiwan

4. Spindle motor :4.5kw HQD water cooling spindle which is good for foam,wood,EPS cutting and milling with low noise and high accurate. This spindle we offer 24 month warranty for free

6. Motors and drivers:Yaksawa servo motor drivers 850w from Japan Original

7. Control system: Famous Mach3 control system that included into computer 32bit or 64bit both no problem. We use ethernet version that no need extra more usb cables more convenient to connect

8. Machine working table:Vacuum table with toughness pvc materials with drawing 8 zones. T-SLOT combination also no problem

9. Cables :We use Germany quality strong cable inside 6 lines make sure many years working no problem

10 Dust collector with pipes:We use dust pipr diameter 30mm and dust brush two holes can working together.Dust device can collect dust and together adsorbded to dust collector well.

11. Vacuum pump:5.5kw or 7.5kw vacuum pump air cooling tyle with noise reducer to make sure low noise

ATC Wood Cnc machine detail parameters:

| Number |

Description |

Parameter |

| 1 |

X,Y,Z Working Area |

1300mmx2500mmx500mm/up to 1500mm z axis height for your option |

| 2 |

Table Size |

1330mm×3140mm |

| 3 |

X,Y,Z Traveling Positioning Accuracy |

±0.03/300 |

| 4 |

X,Y,Z Repositioning Accuracy |

±0.03mm |

| 5 |

Table Surface |

Vacuum and T-slot Combined (Option: T-slot table) |

| 6 |

Frame |

Welded structure |

| 7 |

X, Y Structure |

Rack and Pinion Drive, Hiwin Rail Linear Bearings |

| 8 |

Z Structure |

Hiwin Rail Linear Bearings and Ball Screw |

| 9 |

Automatic tool changer |

Linear type(disc type for option) |

| 10 |

Pieces of tool changer |

10 pieces |

| 11 |

Max. Working Speed |

40000mm/min |

| 12 |

Spindle Power |

4.5kw water cooling spindle |

| 13 |

Spindle Speed |

0-24000RPM |

| 14 |

Drive Motors |

Yaskawa servo motor 850W |

| 15 |

Working Voltage |

AC 380V/50/60Hz,3PH |

| 16 |

Command Language |

G Code |

| 17 |

Operating System |

mach3 system |

| 18 |

Computer Interface |

Ethernet, CF Card |

| 19 |

Flash Memory |

512M(U Disk) |

| 20 |

Collet |

ER32 |

| 21 |

X,Y Resolution |

<0.03mm |

| 22 |

Software Compatibility |

Type3/UcancameV9 software |

| 23 |

Running Environment Temperature |

0 - 45 Centigrade |

| 24 |

Relative Humidity |

30% - 75% |

| 25 |

Packing Size |

3500X2250X2200mm |

| 26 |

N.W. |

1800KG |

| 27 |

G.W. |

2000KG |

| 28 |

Delivery time |

14-20 working days |

Optional parts :

1. Z axis height we can make from 500mm-1500mm as per your requirements

2. Control system we can change to DSP/NK105/WEIHONG/Syntec system

3. Motor and drivers we can change to cheaper Delta servo or Chinese leadshine 850w servo motor drivers

4. We can update z axis to 4 axis cnc with rotate left and right 90 degree

5. Machine table only T-SLOT with clamps also no problem

6. Spindle power we have 3.0kw/5.5kw/6kw/7.5kw water cooling and air cooling spindle for your option

For metal milling like aluminum steel etc we suggest you low rotate speed spindle and for wood,foam etc material working we suggest you high rotate speed spindle

1. Strong machine gantry beam with thickness 12mm

2.Original HIWIN20/30 square rail and helica rack pinion for xyz three axis transmission

3.Careful assembly work

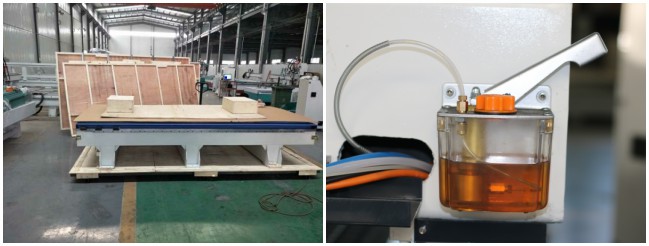

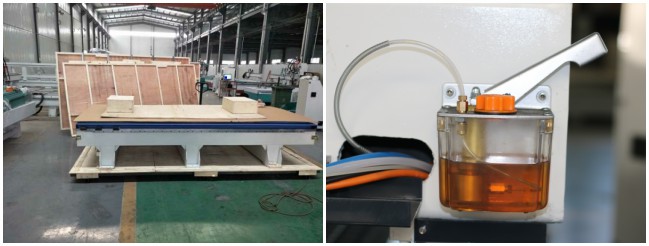

4. Machine body with 3 main legs support more stable and oil pump with manually

5. MACH3 control software with ethernet connection

Machine cutting and engraving samples:

1.1 Foam cutting by cnc router cnc engraving R-1530H

2.1 Wood carving by cnc router cnc engraving machine R-1530

Machine package and delivery:

Rhino CNC Machine package process: This cnc router cnc engraving machine R-1530 height z axis is 500mm so when package the total height will be more than 2.3meter. That is why we need remove gantry beam in seperate box and machine body seperate box.

Rhino CNC Machine package process: This cnc router cnc engraving machine R-1530 height z axis is 500mm so when package the total height will be more than 2.3meter. That is why we need remove gantry beam in seperate box and machine body seperate box.

Firstly machines are inspected by engineers make sure no any problem then we have special workers who are professional for machine pacakge. We use plastic film cover machnes to avoid moisture on the sea then we use strong stap to tight machine all components well like gantry,table,dust collector and control panel etc. Then we will move it on the plywood bottom bracket. Setting it in the proper location then use air nail to fix machine legs well on the bracket. It will take about 1-2 hours then we make a full package with plywood box. Finally we use steel strap tight the whole plywood box and print shipping mark and something else as per customer requirement on outside of box. Now the whole process is finished well and it will take 2-3 hours to package it perfectly.

Welcome to email us for your more detail requirements for this machine!

Welcome to email us for your more detail requirements for this machine!

1. Strong machine gantry beam with thickness 12mm

1. Strong machine gantry beam with thickness 12mm  2.Original HIWIN20/30 square rail and helica rack pinion for xyz three axis transmission

2.Original HIWIN20/30 square rail and helica rack pinion for xyz three axis transmission  3.Careful assembly work

3.Careful assembly work  4. Machine body with 3 main legs support more stable and oil pump with manually

4. Machine body with 3 main legs support more stable and oil pump with manually  5. MACH3 control software with ethernet connection

5. MACH3 control software with ethernet connection