High Precision Metal Milling CNC Machine for Aluminum Steel Copper

Our high precision metal milling cnc machine is professional for aluminum steel copper golden silver jade

cutting milling and drilling perfectly. It is miainly used in metal mold, metal jewelry and jade making industry,

Main features of milling cnc machine R-4040

1. Full cover structure to keep a more clean working environment

2. Function of power off and on continue: If machine working and power off then power on, machine cn remember the power off point in working and continue working at the power off point so that save working time too much

3. With breakpoint memory function:If in machine working the tool broken suddenly please don't worry, machine will remember this broken point and can go on working at same location after you change a new tool

4. Our cnc milling machine R-6060 is heavy structure one with whole cast iron body

5. Net weight 500kg more stronger to make sure more stable in aluminum,steel,golden,silver milling with high precision

6. Increasedt working table height 80cm to more suitable to operate machine and watch the w8orking details

7. Scientific structure to make sure no water leakage on rails

8. Stainless steel water slot with height 20-30cm then no water splash outside

9. Cast iron moving working table is much better for hard metal fix no damage

10. Working table and machine structure connection perfectly with thick steel then no shake in working

11. LED light with 20w-100w as per your requirement is more easier in night working

12. Two fans inside of control box to speed up heating outside

13. Famous electronic parts inside of control box to make sure machine working more safe no failure

14. Control system DSP/Ncstudio/Mach3 three types for your option

Main components detail of metal milling cnc machine R-4040

1. Linear rails: we use famous top quality TAIWAN Original HIWIN brand with 20 size for XY transmission

2. Rails block: we also use the same brand original HIWIN20 high level block

3. Ball screws: Top quality TBI ball screws for XYZ axis with diameter 32mm more stronger to make sure higher accurate

4. Spindle motor: we use 4 bearing water cooling spindle with HQD brand top one in China that is more professinal for metal working( we have 2.2kw and 3.0kw for your option)

5. Cables: we use germany technology 6 lines strong cable to make sure long time use to broken

6. Motos: we use stepper motor 450B with 7NM for working

7. Driver: Leadshine 860H original stepper motor for working (also the servo motor and hy brid servo motor for your option)

8. Inverter: we use Fuling or Sunfar top quality inverter in China

9. Automatic tool sensor: it is available to help customer test the distance between tool point and materials surface

10. Filter and power supply inside of control box also good brand in market

Optional parts of metal milling machine R-4040

1. Spindle motor--we have 2.2kw and 3.0kw with single head and multi heads for your option

2. Motor and drivers--we have hy brid servo motor and drivers and Japan Yaskawa/Panasonic servo motor and drivers and Taiwan Delta servo motor and drivers and Chinese leadshine true servo motor and drivers for your option

3. Control system--- DSP with handle/ Ncstudio with computer and handle wheel/ Mach3 with handle wheel for your option

4. Working size---300mmx300mm/400mmx400mm/600mmx900mm three different size for your option

5. Rotary attachment-- this machine can add rotary with diameter 100mm/150mm no problem

Machine detail components:

1. Rotary attachment with machine for 4 axis working

1. Rotary attachment with machine for 4 axis working

2. XYZ three axis TBI ball screws with diameter 32mm

3. Cast iron table with moving type make sure milling better precision + table four sizes fixed more tightly

3. Cast iron table with moving type make sure milling better precision + table four sizes fixed more tightly

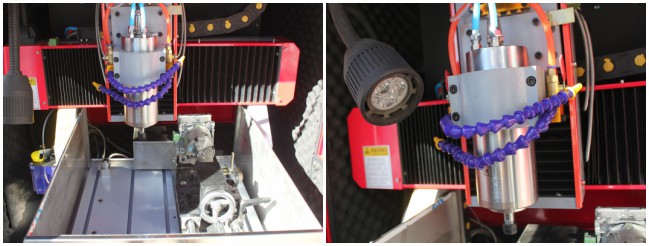

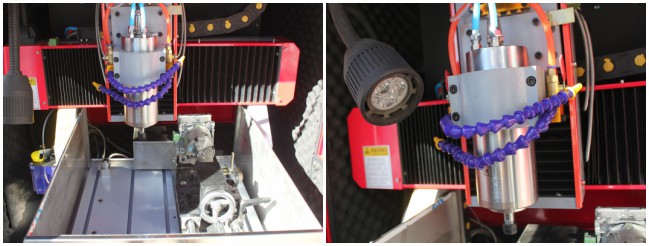

4. High speed water cooling spindle 2.2kw with 4 bearings inside which is more professional for hard material working+LED light

4. High speed water cooling spindle 2.2kw with 4 bearings inside which is more professional for hard material working+LED light

More convenient to watch machine working details at night time

5. Easy servo motor and drivers with 7NM motor and DSP control system handle connection

5. Easy servo motor and drivers with 7NM motor and DSP control system handle connection

6. Advanced automatic tool changer to help you check distance between tool point and material surface

6. Advanced automatic tool changer to help you check distance between tool point and material surface

FAQ :

1. Are you a real factory or trading company?

A: We are manufacture in China more than 15 years that professional for cnc milling machine and other cnc laser machines production.Welcome you visit us at anytime~

2. What is warranty you have?

A: Whole machine 2 years warranty for free and long life time service. Within 2 years any part broken we will send a new one to you for free

3. What is difference 3 axis and 4 axis machine ?

A: 3 axis cnc machine is mainly for surface milling,cutting,engraving and 4 axis is with A axis can work flat and rotary both perfectly.

If with 4 axis system it is good for large produst milling and complicated details no problem.

4. What is different 1.5kw/2.2kw/3.2kw?

1.5kw spindle tool collect max is 6mm but 2.2kw and 3,2kw max tool collect could be 12.7mm. And 2.2kw/3.0kw power is more bigger for milling and cutting,engraving etc.

5. How you inspect this machine?

A: Every machine before delivery we check its working 24 hours continued and inspect all detail parts carefully make sure no any mistake.

Milling samples by R-4040

How we package and delivery this machine

Welcome to send your detail requirements to us by mail at anytime!~

Welcome to send your detail requirements to us by mail at anytime!~