By Serena Zhang | 22 January 2024 | 0 Comments

How to Make 1:1 Car Mold? (Detailed Guidance)

How to Make a Good 1:1 Car Mold? (Detailed Guidance)

In market there have many kinds of car molds like 1:43,1:24,1:18,1:12 etc( this is usually for small size molds). But do you know how to make a large perfect car mold 1:1? What is equipment and software need to make it ?

Today, I will give a detailed instruction about how to make a good 1:1 car mold.

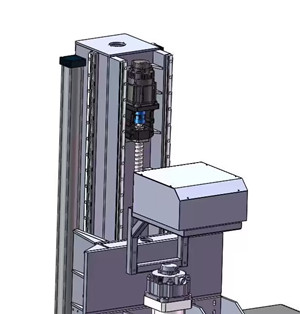

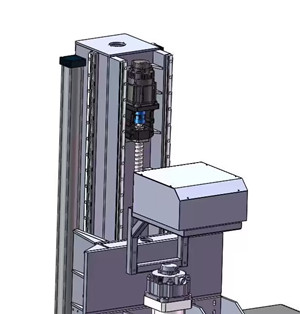

Step 1 : You need to prepare a high quality large size 5 axis cnc router machine professional for car mold making. Like size 2500mmx5000mmx2000mm and 2500mmx6000mmx2000mm etc (machine any working size can be customized as your requirement)

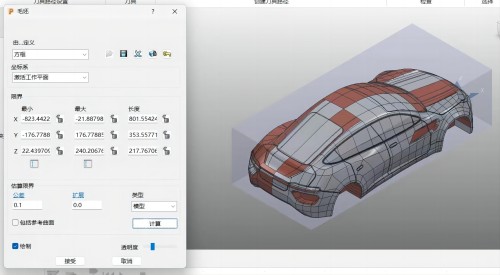

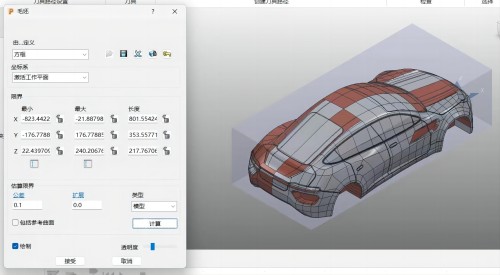

Step 2: You need to have a car model design that made by designers, usually we use PowerMill, AutoCAD, UG,Phulong etc to make a completely 360 degree real 1:1 models

Steps 3: You need prepare some customized tools that model milling, cutting,engraving,grooving etc. Make shape roughly tools, make car model detail compoenets tools etc.

Step 4: Prepare a large piece material of the car mold you need, like Wood,Aluminum,Plastic,PE,Foam etc. Mostly in market use foam materials for 1:1 car making. If don't have some large size material we can connect many blocks together to make it as one project.

Step 5: Find a good engineer who can operate the 5 axis cnc router with Syntec system and ready to make a good 1:1 car mmold now !

Step 1:This is the most important thing in the project means you need a little big investment to get a suitable 5 axis cnc router to help you.

We recommend Rhino CNC high quality 5 axis cnc router 5 axes cnc milling machine RSKM25-H with large working table size 2500mmx6000mmx2000mm.

This machine is with RTCP function (Rotational Tool Center Point) and this function is useful function to measure different tools length automatically to processed material surface, no need you edite in CAD softwares.

Below is RSKM25-H detail technical parameters:

This machine X is with 3 pieces rails and Z is with 4 pieces rails and TBI ball screw for movement.

It is strong enough for all kinds of models making like car models, vessel models,aircraft models and other sculpture engraving also no problem.

It is strong enough for all kinds of models making like car models, vessel models,aircraft models and other sculpture engraving also no problem.

Here is one part of 1:1 car model video for your reference: (if you need more similar videos please feel free to contact us )

Step 2: need to have a car mold design that made by designers, usually we use PowerMill, AutoCAD, UG,Phulong etc to make a completely 360 degree real 1:1 models

Usually we use PM software, its advantages are:

1. Low computer configuration requirements, fast software running speed, and short tool path calculation time greatly improve work efficiency. (Professional testing has shown that UG tool path calculation time is twice that of PM tool path calculation time.).

2. The PM's unique overfitting inspection function ensures that no overfitting occurs in any type of mold (including complex, simple, and some small pieces, rotten surfaces, etc.), making it particularly suitable for beginners.

3. The unique deletion function of PM is currently not available in any programming software on the market. The unique function of PM to delete cutting paths can delete some unnecessary small cutting paths, as well as unnecessary cutting paths due to inadequate consideration in the early stage, which can save a lot of time in recalculating cutting paths.

4. PM software has a simple interface and powerful functions, making it easy for beginners to get started and control the tool path. The quality requirements for mold drawings are also very low, especially in processing shops where mold drawings are often damaged or have small pieces. PM can also generate good tool paths, greatly improving the quality of the mold after processing.

5. PM software has high processing efficiency. In contrast, the tool path simulation time calculated by PM software is closest to the actual processing time, and the tool path is also optimized.

Steps 3: You need prepare some customized tools that model milling, cutting,engraving,grooving etc. Make shape roughly tools, make car model detail compoenets tools etc.

The main several tools are shape roughly tools, all kinds of detailed milling tools, all kinds of detailed engraving tools,Here show you some : (The tools length is more than 100mm and we can customized it as per customer detail requirements)

Step 4: Prepare a large piece material of the car model you need, like Wood,Aluminum,Plastic,PE,Foam etc. Mostly in market use foam materials for 1:1 car making

Here some samples 1:1 car models made by Rhino 5 axis cnc router machine :

Step 5: Find a good engineer who can operate the 5 axis cnc router with Syntec system and ready to make a good 1:1 car model now !

For this steps we can not give you enough advised but with our engineer assistance your engineers will operate well fast. Usually we can send our engineers to your factory to give machine installation and software training.

And Syntec fast speed 5 axis cnc program &manual are saved in CD together delivery to you with machine .

Above are the steps of how to make a 1:1 car models, it is not a easy job but it is not complicated also. This is a very good business and full of challenge.

Something new is the high quality 5 axis cnc router you need to learn and study, here also some other models with different functions for your reference:

Wood 5 axis cnc router Table move 5 axis cnc router Gantry move 5 axis cnc router Other related 5 axis cnc router / 5 axis cnc milling machine articles:

Wood 5 axis cnc router Table move 5 axis cnc router Gantry move 5 axis cnc router Other related 5 axis cnc router / 5 axis cnc milling machine articles:

How to Buy / Find a Good Quality 5 Axis CNC Machine - Detailed Guide (rhinocncmachine.com)

What is Good Quality 3D Wood Mold CNC Router Machines (rhinocncmachine.com)

The New Technology of 5 AXIS CNC Router CNC Milling Machine (rhinocncmachine.com)

In market there have many kinds of car molds like 1:43,1:24,1:18,1:12 etc( this is usually for small size molds). But do you know how to make a large perfect car mold 1:1? What is equipment and software need to make it ?

Today, I will give a detailed instruction about how to make a good 1:1 car mold.

Step 1 : You need to prepare a high quality large size 5 axis cnc router machine professional for car mold making. Like size 2500mmx5000mmx2000mm and 2500mmx6000mmx2000mm etc (machine any working size can be customized as your requirement)

Step 2: You need to have a car model design that made by designers, usually we use PowerMill, AutoCAD, UG,Phulong etc to make a completely 360 degree real 1:1 models

Steps 3: You need prepare some customized tools that model milling, cutting,engraving,grooving etc. Make shape roughly tools, make car model detail compoenets tools etc.

Step 4: Prepare a large piece material of the car mold you need, like Wood,Aluminum,Plastic,PE,Foam etc. Mostly in market use foam materials for 1:1 car making. If don't have some large size material we can connect many blocks together to make it as one project.

Step 5: Find a good engineer who can operate the 5 axis cnc router with Syntec system and ready to make a good 1:1 car mmold now !

Step 1:This is the most important thing in the project means you need a little big investment to get a suitable 5 axis cnc router to help you.

We recommend Rhino CNC high quality 5 axis cnc router 5 axes cnc milling machine RSKM25-H with large working table size 2500mmx6000mmx2000mm.

This machine is with RTCP function (Rotational Tool Center Point) and this function is useful function to measure different tools length automatically to processed material surface, no need you edite in CAD softwares.

Below is RSKM25-H detail technical parameters:

| Model | RSKM25-H |

| Working size | X:5500*Y:2500*Z:2000mm |

| Table size | 7880*4550mm*5100mm |

| Body structure | Steel structure |

| Gantry structure | Customized strength steel welded make sure 5500mm movement stable |

| Working table | Thick Steel welded T-SLOT working table |

| X/Y/Z Working accuracy | ±0.1mm/±0.05mm |

| X/Y/Z Repositioning accuracy | ±0.1mm/±0.05mm |

| B/C rotate accuracy | - 60/20 arc sec |

| Traveling speed | 40m/min |

| Working speed | 25m/min |

| Spindle | Italy HITECO 5 axis water cooling spindle 15KW with HSK-63F ER40 |

| Spindle rotary speed | 0-24000rpm |

| 5 axis part | B axis +-135 degree/C axis +-320 degree |

| Control system | Taiwan Syntec system 5 axis 610MA-E5 |

| Drive and motor | JAPAN YASKAWA brand servo motor drivers with encoder+ Japan Shimpo reducer motor |

| Transmission mode | 4010mm TBI ball screw for Z axis &HIWIN40 square rail 5020mm TBI ball screw for X axis&HIWIN45 square rail 2M Helical gear rack for Y axis &HIWIN 45 square rail |

| Working voltage | AC380V/60HZ&50hz |

| Command language | G-code,*u00,*mmg,*plt |

| Dust collector | Available |

| Oiling system | Automatic oiling |

| Machine weight | 7000kg-10000KG |

| ATC | Linear tool changer 12 pieces |

| Packaging Measure | 880cm*360cm*520cm |

It is strong enough for all kinds of models making like car models, vessel models,aircraft models and other sculpture engraving also no problem.

It is strong enough for all kinds of models making like car models, vessel models,aircraft models and other sculpture engraving also no problem.Here is one part of 1:1 car model video for your reference: (if you need more similar videos please feel free to contact us )

Step 2: need to have a car mold design that made by designers, usually we use PowerMill, AutoCAD, UG,Phulong etc to make a completely 360 degree real 1:1 models

Usually we use PM software, its advantages are:

1. Low computer configuration requirements, fast software running speed, and short tool path calculation time greatly improve work efficiency. (Professional testing has shown that UG tool path calculation time is twice that of PM tool path calculation time.).

2. The PM's unique overfitting inspection function ensures that no overfitting occurs in any type of mold (including complex, simple, and some small pieces, rotten surfaces, etc.), making it particularly suitable for beginners.

3. The unique deletion function of PM is currently not available in any programming software on the market. The unique function of PM to delete cutting paths can delete some unnecessary small cutting paths, as well as unnecessary cutting paths due to inadequate consideration in the early stage, which can save a lot of time in recalculating cutting paths.

4. PM software has a simple interface and powerful functions, making it easy for beginners to get started and control the tool path. The quality requirements for mold drawings are also very low, especially in processing shops where mold drawings are often damaged or have small pieces. PM can also generate good tool paths, greatly improving the quality of the mold after processing.

5. PM software has high processing efficiency. In contrast, the tool path simulation time calculated by PM software is closest to the actual processing time, and the tool path is also optimized.

Steps 3: You need prepare some customized tools that model milling, cutting,engraving,grooving etc. Make shape roughly tools, make car model detail compoenets tools etc.

The main several tools are shape roughly tools, all kinds of detailed milling tools, all kinds of detailed engraving tools,Here show you some : (The tools length is more than 100mm and we can customized it as per customer detail requirements)

Step 4: Prepare a large piece material of the car model you need, like Wood,Aluminum,Plastic,PE,Foam etc. Mostly in market use foam materials for 1:1 car making

Here some samples 1:1 car models made by Rhino 5 axis cnc router machine :

Step 5: Find a good engineer who can operate the 5 axis cnc router with Syntec system and ready to make a good 1:1 car model now !

For this steps we can not give you enough advised but with our engineer assistance your engineers will operate well fast. Usually we can send our engineers to your factory to give machine installation and software training.

And Syntec fast speed 5 axis cnc program &manual are saved in CD together delivery to you with machine .

Above are the steps of how to make a 1:1 car models, it is not a easy job but it is not complicated also. This is a very good business and full of challenge.

Something new is the high quality 5 axis cnc router you need to learn and study, here also some other models with different functions for your reference:

Wood 5 axis cnc router Table move 5 axis cnc router Gantry move 5 axis cnc router Other related 5 axis cnc router / 5 axis cnc milling machine articles:

Wood 5 axis cnc router Table move 5 axis cnc router Gantry move 5 axis cnc router Other related 5 axis cnc router / 5 axis cnc milling machine articles:How to Buy / Find a Good Quality 5 Axis CNC Machine - Detailed Guide (rhinocncmachine.com)

What is Good Quality 3D Wood Mold CNC Router Machines (rhinocncmachine.com)

The New Technology of 5 AXIS CNC Router CNC Milling Machine (rhinocncmachine.com)

Leave a Reply

Your email address will not be published.Required fields are marked. *