By Serena Zhang | 07 July 2023 | 0 Comments

How Does a Laser Welding Machine Work

How Does a Laser Welding Machine Work ?

Laser welding machine has developed in market for more than 20 years. Now it have many different working models with different power from 100w to 3000w as full automatic laser welding machine, desktop laser welding machine , Jewellery laser welding machine, fiber laser welding machine etc.

Today we will introduce the most popular one in market recently- Handheld Fiber Laser Welding Machine with its working performance (how does the handheld fiber laser welding machine work ?)

Why this handheld fiber laser welding machine become the most popular one in market now?

1.The handheld fiber laser welding machine uses a handheld welding gun, which overcomes the limitations of the working table space.

There is no limit when welding, and it can meet the requirements of multi angle and multi direction welding. It can complete the position and narrow space of the workpiece that cannot be welded automatically, which makes it more flexible.

2. The front end of the welding gun of the handheld laser welding machine is usually equipped with a copper nozzle. The copper nozzle can be next to the workpiece during welding, reducing the weight of the welding gun and increasing the stability of welding. The handheld welding gun can move along the shape of the workpiece and complete welding, whether it is a conventional or a profiled welding.

3. The handheld fiber laser welding machine has extremely high precision, small laser beam focusing diameter, and less impact on surrounding materials during the welding process, which avoids the material damage that is easy to occur in the traditional welding process. For more vulnerable materials, it can also reduce subsequent processing and improve production efficiency.

4. The handheld fiber laser welding machine has fast welding speed and high welding efficiency, which is particularly prominent in mass production; In addition, the handheld laser welding machine can also adapt to the automated production line and realize fully automated operation, which can not only ensure the product quality, but also significantly shorten the product production cycle.

Welding performance and Application industry

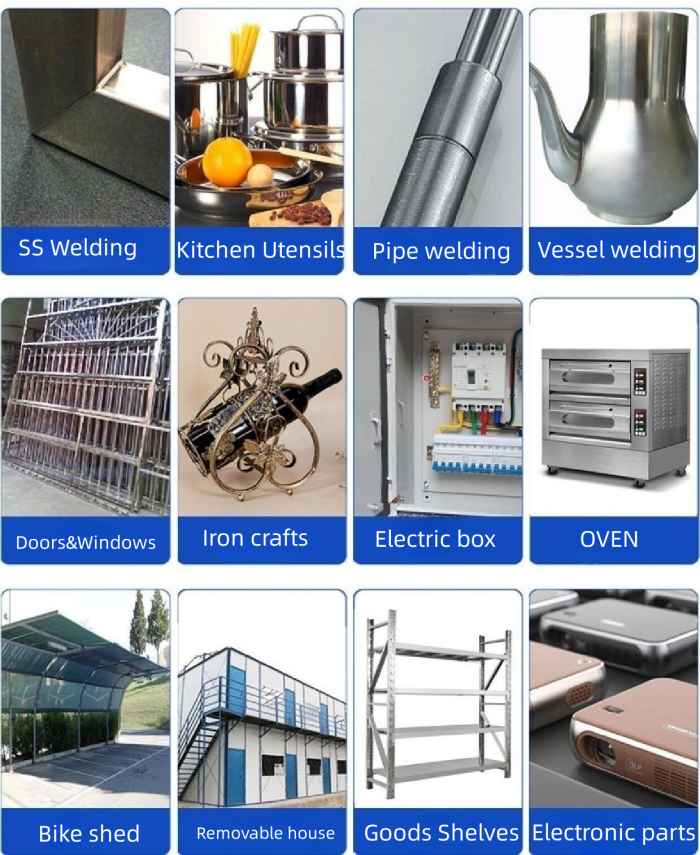

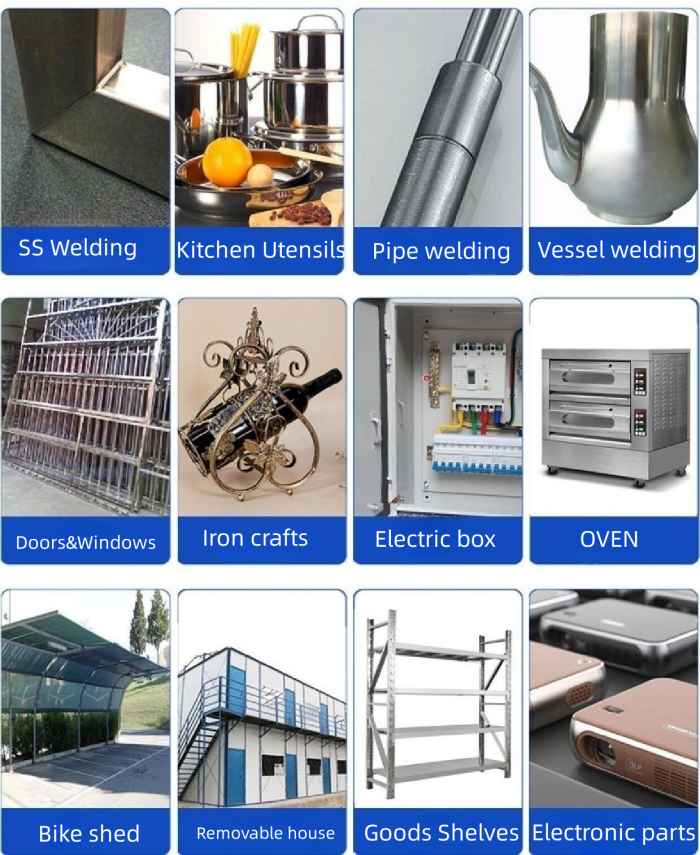

It widely used in Stainless Steel welding , Kitchen utensils,pipes welding , Vessel welding, doors and windows,Iron crafts , electric box , Oven ,Bike shed , removable house , Goods shelves, electronic parts etc.

If want to know more detailed how does it work, firstly we should know machine main components:

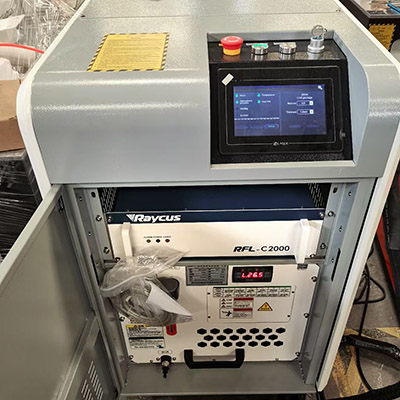

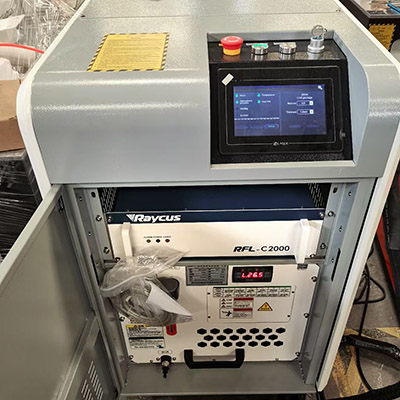

1. RECI Fiber laser source installed into the handheld fiber laser welding machine, its power from 1000w-2000w

2.MAX Fiber laser source installed into the laser welding machine, the power from 1000w-3000w

3.Most popular is Raycus fiber laser source ,it has 1000w,1500w,2000w,3000w for option

4. JPT Fiber laser source also is popular, its power from 1000w-4000w

Different customers will choose different brand laser source installed into this handheld fiber laser welding machine.

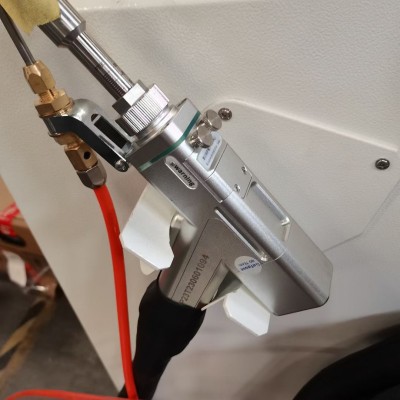

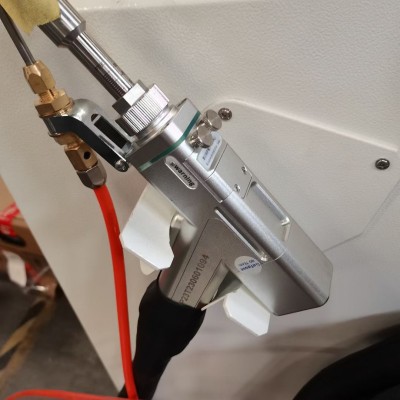

Next component is the welding gun that is very important also !

Different welding gun with different functions, if you want to know details welcome to contact us and we will explain clearly for it !

After you are clear for machine main components the next machine install and working :

This is a completely ready machine when you receive and you only need to do 3 steps mainly:

1. Connection air pump with machine

2. Put enough pure water into water chiller

3. Connect machine main power cable with your local power (If the plug not proper please use converter)

1 . Connection air pump with machine

Here is the air pump that you should connect with machine behind side (there have pipes to connect )

2. Put enough pure water into water chiller

Open the door of machine and there is the water chiller that you need put pure water inside

3. Connect machine main power cable with your local power (If the plug not proper please use converter)

Machine voltage is 220v single phase and you should connect with main power properly then OK

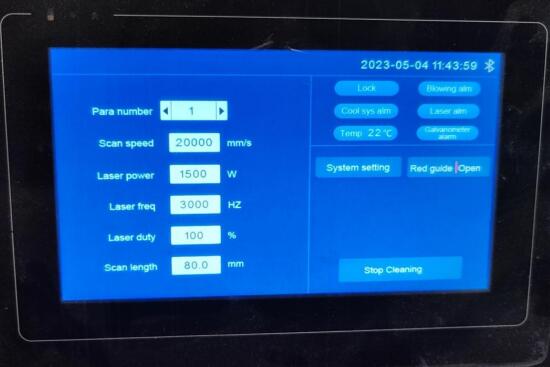

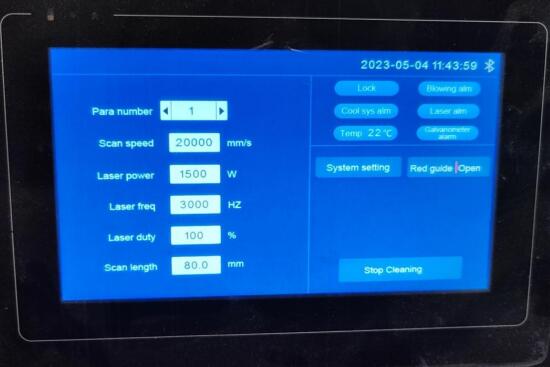

Control screen explanation :(Scanning parameters: used to set the related parameters during galvanometer scanning

1. No.: different parameter numbers can be used to set many sets of various welding parameters.2.welding speed: used to set the scanning speed of galvanometer Usually set 20000mm/s

3.Laser power: used to set the percentage of laser peak power. Usually set 1500 (if the laser source is 1500w)

4.Laser frequency: used to set the PWM frequency of laser Usually set 5000HZ

5.Duty cycle: used to set PWM signal duty cycle of continuous laser. Usually set 100

6.welding length: used to set the laser welding length Usually set 80-10

Also have some tips in handheld fiber laser welding machine working need to be more careful:

1.The laser welding machine can weld thin-walled materials and precision parts, and carry out all directional operations such as butt welding, fillet welding and overlap welding.

2.The welding methods include continuous Laser beam welding, pulse Laser beam welding and electron beam welding.

3.Wire feeding addition is considered according to the workpiece conditions.

4.Attention shall be paid during the operation of the laser welding machine. Do not touch the laser beam with your hands or other body parts. Do not directly shoot yourself or others with the gun of the laser welding machine

Here some Laser welding machines from Rhino CNC that suggested to you:

Laser welding machine has developed in market for more than 20 years. Now it have many different working models with different power from 100w to 3000w as full automatic laser welding machine, desktop laser welding machine , Jewellery laser welding machine, fiber laser welding machine etc.

Today we will introduce the most popular one in market recently- Handheld Fiber Laser Welding Machine with its working performance (how does the handheld fiber laser welding machine work ?)

Why this handheld fiber laser welding machine become the most popular one in market now?

1.The handheld fiber laser welding machine uses a handheld welding gun, which overcomes the limitations of the working table space.

There is no limit when welding, and it can meet the requirements of multi angle and multi direction welding. It can complete the position and narrow space of the workpiece that cannot be welded automatically, which makes it more flexible.

2. The front end of the welding gun of the handheld laser welding machine is usually equipped with a copper nozzle. The copper nozzle can be next to the workpiece during welding, reducing the weight of the welding gun and increasing the stability of welding. The handheld welding gun can move along the shape of the workpiece and complete welding, whether it is a conventional or a profiled welding.

3. The handheld fiber laser welding machine has extremely high precision, small laser beam focusing diameter, and less impact on surrounding materials during the welding process, which avoids the material damage that is easy to occur in the traditional welding process. For more vulnerable materials, it can also reduce subsequent processing and improve production efficiency.

4. The handheld fiber laser welding machine has fast welding speed and high welding efficiency, which is particularly prominent in mass production; In addition, the handheld laser welding machine can also adapt to the automated production line and realize fully automated operation, which can not only ensure the product quality, but also significantly shorten the product production cycle.

Welding performance and Application industry

It widely used in Stainless Steel welding , Kitchen utensils,pipes welding , Vessel welding, doors and windows,Iron crafts , electric box , Oven ,Bike shed , removable house , Goods shelves, electronic parts etc.

If want to know more detailed how does it work, firstly we should know machine main components:

1. RECI Fiber laser source installed into the handheld fiber laser welding machine, its power from 1000w-2000w

2.MAX Fiber laser source installed into the laser welding machine, the power from 1000w-3000w

3.Most popular is Raycus fiber laser source ,it has 1000w,1500w,2000w,3000w for option

4. JPT Fiber laser source also is popular, its power from 1000w-4000w

Different customers will choose different brand laser source installed into this handheld fiber laser welding machine.

Next component is the welding gun that is very important also !

Different welding gun with different functions, if you want to know details welcome to contact us and we will explain clearly for it !

After you are clear for machine main components the next machine install and working :

This is a completely ready machine when you receive and you only need to do 3 steps mainly:

1. Connection air pump with machine

2. Put enough pure water into water chiller

3. Connect machine main power cable with your local power (If the plug not proper please use converter)

1 . Connection air pump with machine

Here is the air pump that you should connect with machine behind side (there have pipes to connect )

2. Put enough pure water into water chiller

Open the door of machine and there is the water chiller that you need put pure water inside

3. Connect machine main power cable with your local power (If the plug not proper please use converter)

Machine voltage is 220v single phase and you should connect with main power properly then OK

Control screen explanation :(Scanning parameters: used to set the related parameters during galvanometer scanning

1. No.: different parameter numbers can be used to set many sets of various welding parameters.2.welding speed: used to set the scanning speed of galvanometer Usually set 20000mm/s

3.Laser power: used to set the percentage of laser peak power. Usually set 1500 (if the laser source is 1500w)

4.Laser frequency: used to set the PWM frequency of laser Usually set 5000HZ

5.Duty cycle: used to set PWM signal duty cycle of continuous laser. Usually set 100

6.welding length: used to set the laser welding length Usually set 80-10

Also have some tips in handheld fiber laser welding machine working need to be more careful:

1.The laser welding machine can weld thin-walled materials and precision parts, and carry out all directional operations such as butt welding, fillet welding and overlap welding.

2.The welding methods include continuous Laser beam welding, pulse Laser beam welding and electron beam welding.

3.Wire feeding addition is considered according to the workpiece conditions.

4.Attention shall be paid during the operation of the laser welding machine. Do not touch the laser beam with your hands or other body parts. Do not directly shoot yourself or others with the gun of the laser welding machine

Here some Laser welding machines from Rhino CNC that suggested to you:

Leave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG