By Serena Zhang | 18 March 2025 | 0 Comments

How to Operate the Hand-held Fiber Laser Welding Machine 4 in 1 ?

How to Operate the Hand-held Fiber Laser Welding Machine 4 in 1 ?

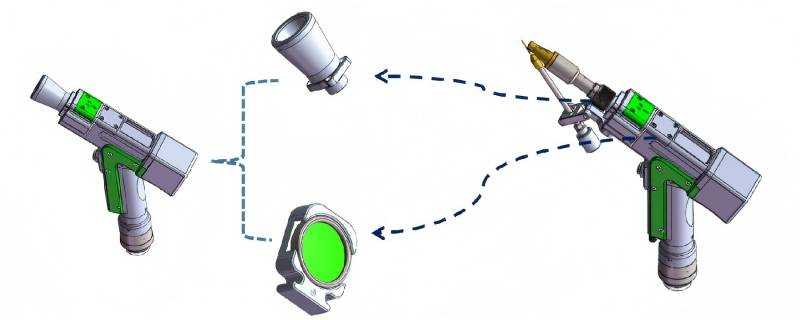

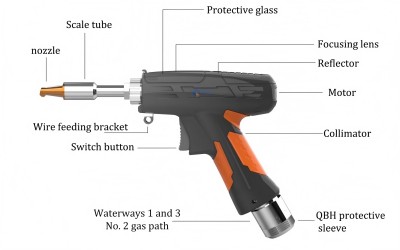

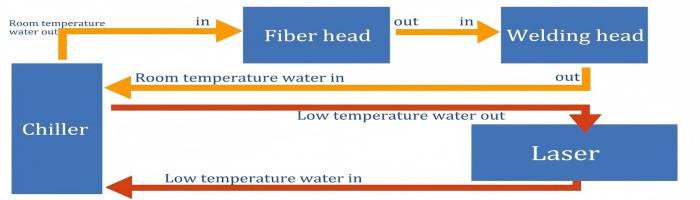

1. Introduce of laser welding machine torch gun:

Protective shell: protects internal precision components, dust and earthquake resistance.

Fiber optic fixture: V-groove fixed fiber optic, spring/pneumatic clamping to prevent displacement.

Electrode and motor: The electrode discharge melts the optical fiber (2000 ℃+), and the motor is fine tuned to achieve sub micron level precise alignment.

Optical system: dual protective mirrors, real-time monitoring of alignment and cutting quality.

Heating protection: Heat shrink tubing encapsulates fusion points to enhance durability.

Realize fast and low loss fusion splicing of optical fibers (<0.02dB) to ensure stable transmission of communication signals.

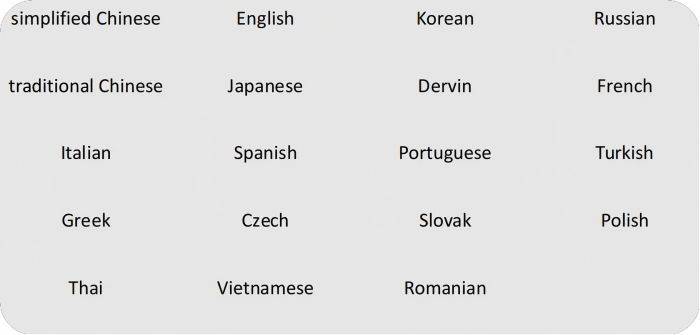

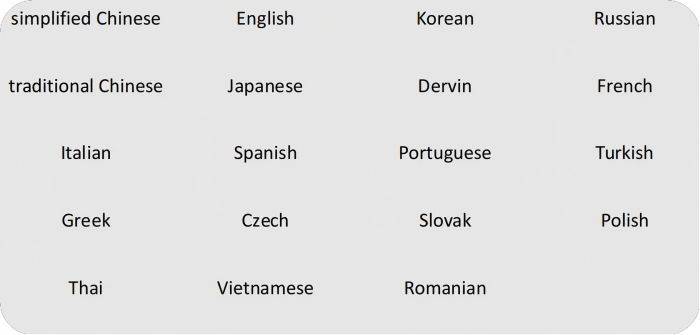

2. Control system language choose :

Rhino hand-held fiber laser welding machine system support 19 languages:

Simplified Chinese/English/Korean/Russian/Traditional Chinese/Japanese/Dervin/French/Italian/Spanish/Portuguese/Turkish/Greek/Czech/Slovak/Polish/Thai/Vietnamese/Romanian

3. Welding mode operation steps:

Related popular laser welding machine recommend:

Rhino Raycus 2000w Hand-Held Metal Fiber Laser Welding Machine Laser Welder RFW-2000

Rhino Raycus 2000w Hand-Held Metal Fiber Laser Welding Machine Laser Welder RFW-2000

RHF-1000 is popular handheld fiber laser welding machine with 1kw raycus fiber source,used for all kinds of materials welding like stainless steel,carbon steel,aluminum,copper,brass etc. Also can cut thin metal with hand-held torch.

Hand-held fiber laser welding machine become more and more popular in market now but not all customers know how to operate it well especially the multi function 4 in 1 laser welder machine.This article is introduced to all new users and hope everyone can use it perfectly to increase their business scale.

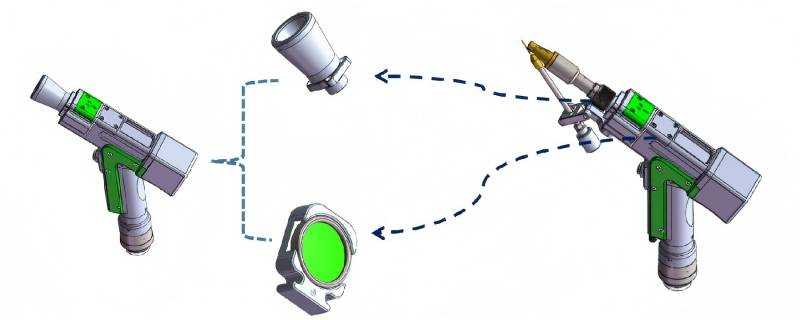

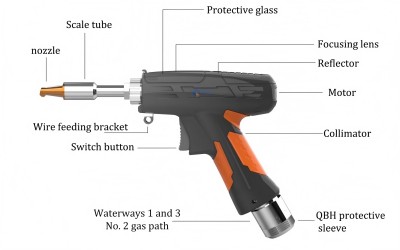

1. Introduce of laser welding machine torch gun:

Protective shell: protects internal precision components, dust and earthquake resistance.

Fiber optic fixture: V-groove fixed fiber optic, spring/pneumatic clamping to prevent displacement.

Electrode and motor: The electrode discharge melts the optical fiber (2000 ℃+), and the motor is fine tuned to achieve sub micron level precise alignment.

Optical system: dual protective mirrors, real-time monitoring of alignment and cutting quality.

Heating protection: Heat shrink tubing encapsulates fusion points to enhance durability.

Realize fast and low loss fusion splicing of optical fibers (<0.02dB) to ensure stable transmission of communication signals.

2. Control system language choose :

Rhino hand-held fiber laser welding machine system support 19 languages:

Simplified Chinese/English/Korean/Russian/Traditional Chinese/Japanese/Dervin/French/Italian/Spanish/Portuguese/Turkish/Greek/Czech/Slovak/Polish/Thai/Vietnamese/Romanian

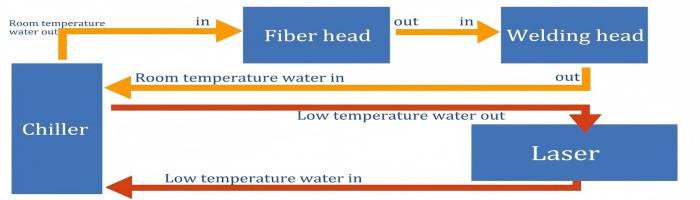

3. Welding mode operation steps:

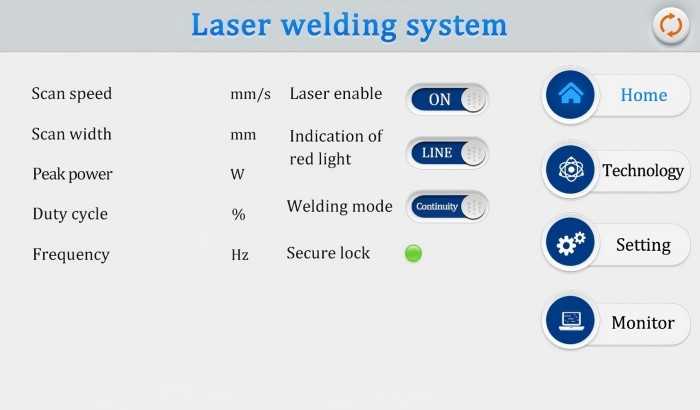

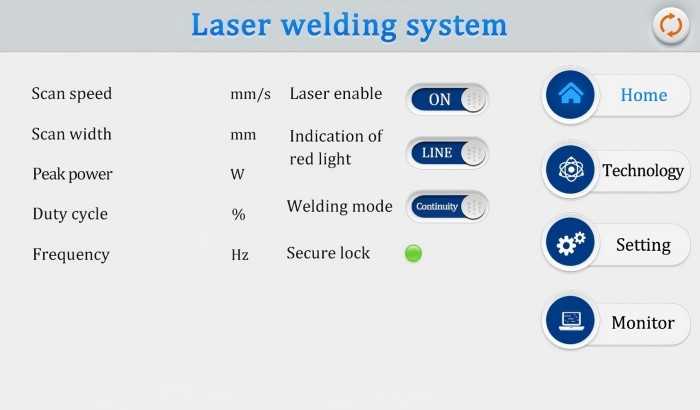

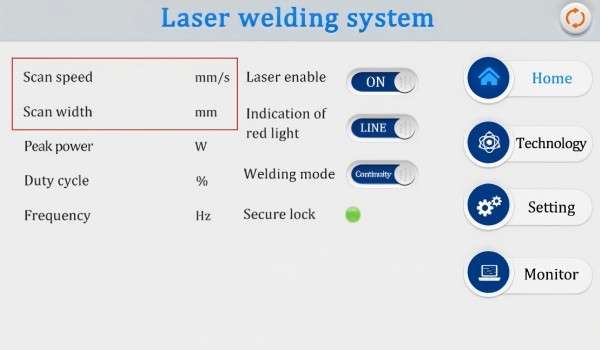

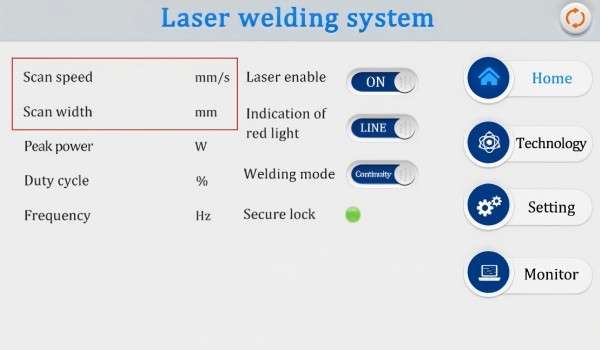

① This interface can see the current process parameters (this page can not be modified process) and real-time alarm

information.

information.

② The default is ON, the red light is LINE by default, and the welding mode is continuous. When the enabling is turned off, the enabling signal will not be sent to the laser and can be used to test the outlet function. Close the red light

indicator, the14th motor stops swinging, and the red light is a point to adjust the center position. The welding mode is divided into continuous and spot welding. When the spot welding is selected, the spot welding type needs to be set in the setting page.

indicator, the14th motor stops swinging, and the red light is a point to adjust the center position. The welding mode is divided into continuous and spot welding. When the spot welding is selected, the spot welding type needs to be set in the setting page.

③ The safety lock is divided into gray and green. When the metal clip is clamped on the processing piece and the copper nozzle of the gun body contacts the processing piece, the 5 and 6 feet of the signal interface 1 are connected, and the safety lock indicator light is displayed as green. At this time, the light can be realized according to the trigger.

④ Click on the upper right corner to switch to the cleaning mode.

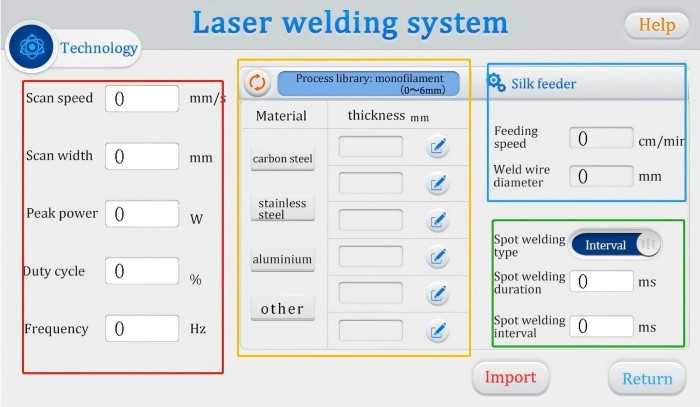

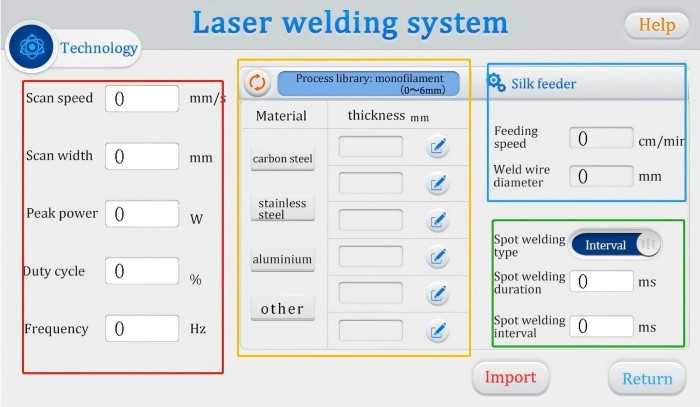

At present, the process page provides a self-editable [process library] function for users to save the parameters. The definition and scope of the process parameters are introduced below:

1. Red frame is the welding process parameters

2. Yellow box is the [process library] parameter

3.Green box are spot weld type parameters

4.Blue boxes are the parameters of the wire feeder

1. Red frame is the welding process parameters

2. Yellow box is the [process library] parameter

3.Green box are spot weld type parameters

4.Blue boxes are the parameters of the wire feeder

③ Basic information of the equipment of Rhino hand-held fiber laser welding machine

Equipment authorization: click to encrypt the use time of the equipment.

When the equipment is used for more than the set time, the authorization will be terminated and the system will stop working. Factory default is long-term effective, if you need encryption and decryption, please contact us for inquiry.

System version: three sets of numbers, the first group is the hardware version,

the second group is the microcontroller program version, the third group is the

touch screen version.

4. Cutting mode steps

5. Cleaning mode steps

[Scan width] is set to [0], which refers to the [copper mouth] for replacing

cutting, which can be cut.[safe ground lock] needs to be ensured.

5. Cleaning mode steps

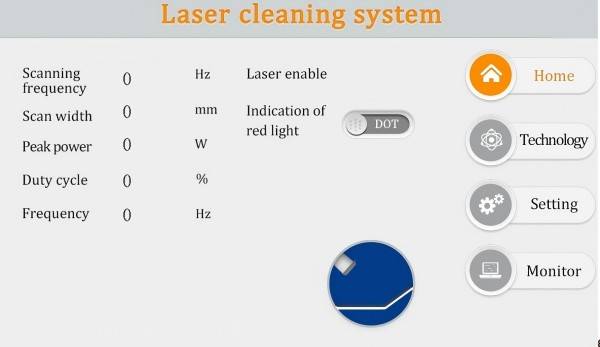

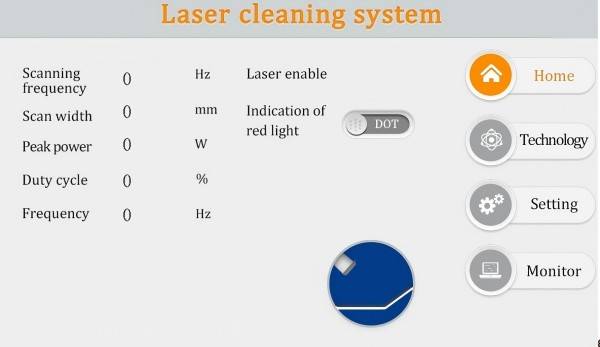

① This interface can see the current process parameters (this page can not be modified process) and real-time alarm information.

② The default state is ON, indicating that the red light is LINE by default. When the enabling is turned off, the enabling signal will not be sent to the laser and can be used to test the outlet function. Close the red light indicator, the motor stops swinging, and the red light is a point to adjust the center position.

③ Click on the upper right corner to switch between the cleaning mode

① The process interface contains the process parameters of debugging, click the box (red) to modify, click OK, and then save in the quick process, click import (modify-save-import).

② The scan frequency range is 10-100 HZ, and the scan width range is 0 -30mm. (At the focusing lens F800, the maximum width is 130mm. At the focusing mirror F150, the maximum width is 30mm).

③ Peak power should be less than or equal to the parameter page laser power.

(If the laser power is 1000W, then this value is not higher than 1000).

④ Duty cycle range 0 to 100 (default 100, usually not changed).

⑤ The pulse frequency range is recommended from 5-5000Hz (default 2000, usually no modification).

⑥ Click the "Help" button on the top right to get more relevant parameter explanations.

⑦ After modifying the parameters, you can see whether the import is successful on the home page.

⑧ Reference process, can be used in the small program process reference.

6. Welding seam cleaning steps

Change the [AS-2.0D] copper nozzle in the welding mode. For the specific process,

see the wechat small program demonstration video.

More information welcome to contact Rhino CNC team .

More information welcome to contact Rhino CNC team .

7. Maintenance

Maintenance and replacement method of related lenses:

① Before operation, please clean your hands and dry them, and then wipe them with cotton and alcohol again.

② Open the protective mirror in a relatively dust-free place, focus the mirror compartment cover, pull out the lens bracket, do a good job of protection (beautiful paper cover), check the protective lens, if there is an obvious burning point on the lens surface, should be directly replaced.

③ Then check the white storage seal ring under the lens.(If the storage sealing ring cannot be used, it must be replaced immediately.

④ Wipe the warehouse mouth and the inside of the warehouse cover with a cotton ball dipped in alcohol, quickly insert the protective lens bracket into the protective mirror compartment, and lock the screws.

Related popular laser welding machine recommend:

Rhino Raycus 3000w Fiber Laser Welder Machine (hand-held) Laser Welder RFW-3000

This is Rhino new technology handheld 3000w fiber laser welder machine,that uses fiber laser to weld metal materials.

Commonly used for manufacturing industrial products such as automotive, aircraft, and electronic components.

It can weld metal materials and complete the work in a very short time.

There have 1000w/1500w/2000w/3000w for option

This is Rhino new technology handheld 3000w fiber laser welder machine,that uses fiber laser to weld metal materials.

Commonly used for manufacturing industrial products such as automotive, aircraft, and electronic components.

It can weld metal materials and complete the work in a very short time.

There have 1000w/1500w/2000w/3000w for option

This is Rhino new technology handheld fiber laser welding machine,that uses fiber laser to weld metal materials

Commonly used for manufacturing industrial products such as automotive, aircraft, and electronic components.

It can weld metal materials and complete the work in a very short time.

There have 1000w/1500w/2000w/3000w for option .

Also laser cleaning and laser cutting function can be added by this machine.

More details welcome to contact RhinoCNC at anytime

Commonly used for manufacturing industrial products such as automotive, aircraft, and electronic components.

It can weld metal materials and complete the work in a very short time.

There have 1000w/1500w/2000w/3000w for option .

Also laser cleaning and laser cutting function can be added by this machine.

More details welcome to contact RhinoCNC at anytime

Leave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG

- How to Use Epoxy Resin? (from raw materials to precise models for beginners)

- What is RTCP in CNC ? (Detailed more than 2000 words)

- How to Make a Complex Mold by the 5-Axis CNC Machining - The Ultimate Guide Exceeds 2000 Letters

- How to Operate the Hand-held Fiber Laser Welding Machine 4 in 1 ?

- Can a CNC Router Cut Aluminum ?