By Serena Zhang | 12 January 2024 | 0 Comments

How Much dose 5 Axis CNC Router Machine Cost ?

How Much dose 5 Axis CNC Router Machine Cost ?

Why the price of 5 axis cnc router machine have so big difference ? How much does a 5 axis cnc router cost usually?

Some cheaper 5 axis cnc mill machine price rang from $20000usd to $40000usd and some expensive 5 axis cnc router price rang from $50000usd to $100000usd etc.

There are many factors that determine the price.

Today, we will analyze the price reasons of 5-axis engraving machines from the most basic aspects:

1. Machine Weight

2. Machine specifications

3. Technology of production assemble

4. Supplier Brand & Reputation

1. Machine weight :

1) Structure : Different frame structure of 5 axis cnc router machine the weight is different. We talking from the movable robot arm 5 axis and 6 axis cnc machine, What is the key difference between robot arm and industry 5 axis cnc router? It is the weight different ! Because of robot arm machine is very light about 300-500kg so it can move anywhere and very flexible. So the price is much cheaper than the industry 5 axis cnc router.

Robot arm mold cnc machine like 5 axis 6 axis the price rang from 20000usd to 40000usd .

But for gantry movement 5 axis cnc router the weight is too much heavier than above robot arm.

As Gantry movement 5 axis cnc milling machine the net weight at least more than 3000KG to make sure the good working rigidity. Like Rhino 5 axis cnc router 4ft by 8ft table size the total net weight is 6000kg and others light structure weight should be 3000kg about.

Same machine model (means same working table size ) different supplier the machine weight is different also. The cost is different and increased 1500USD when the total weight increasing every 1000kg . Like suppliers offer one 5 axis cnc router with table size 4ft by 8ft and weight 30000kg price 50000USD, the other supplier offer same table size machine but machine net weight 6000kg so machine cost will be increased at least 4500USD.

What is gantry move 5 axis cnc router:

2). Machine working table size : Different table size means machine weight is different also.More bigger size the total weight is more heavier .

5 axis cnc router table size can be customized usually the popular size is like 1300mmx2500mm/1500mmx3000mm/2000mmx3000mm/3000mmx6000mm and more. The Z axis height from 1000mm to 2000mm etc.

So different machine table size the machine price is different also.

Especially, the Z-axis height plays a crucial role in the cost of the 5 axis cnc machine. If height increase from 1000 to 1500mm the cost little, but if height from 1000mm to 2000mm the total cost will increase too much because z axis high is so high need to make sure the table well.

Therefore, before purchasing a 5 axis cnc router machine, it is necessary to consider your own usage needs and scenarios, as well as factors such as whether the equipment needs to be frequently moved.

2. Machine specifications

The obvious truth that everyone understands different machine specifications the machine price different also.

5 axis cnc machine main parts are below:

1). Spindle : there have many 5 axis spindle like water cooling and air cooling with different power for option.

Usually water cooling spindle is recommended better than air cooling spindle. Power like 10kw/11kw/13kw/15kw etc.

5 axis spindle brand usually RhinoCNC use top quality Hiteco brand from Italy and in market also have some cheaper price brand spindles made in China and other countries.

2)Control PLC: Here mostly use is Synte 610WA 5 axis that support 6 axis and 7 axis also and with the most important function RTCP ! This system operation is very convenient, fast, and powerful! The new generation five axis system is a highly popular CNC system in the industry, which is very easy to learn and use, user-friendly to operate, especially the handwheel simulation program is very convenient!

Also have other a little more expensive PLC controller like Italy OSAI, Germany Siemens, Japan Fanuc etc. So the most economic and friendly system we recommend is TAIWAN Syntec 5 axis PLC system !

3) Machine Servo Motor Drivers: Usually in market the popular and durable servo motor is equipped with Syntec system. It is Syntec Bus absolute value servo motor drivers. Its advantages are fast signal propagation speed and low susceptibility to infection.

Below is the electronic box inside photo :

4) Other mechanical transmission parts: Like rails, ball screw and rack.

The cheaper rails have TWINS brand so total machine cost will be cheaper also. The original HIWIN/PMI square rails price is much higher than TWINS brand. HIWIN square rails size have HIWIN20/25/30/35/45/55 for option. Usually more bigger size 5 axis cnc milling machine the rail size will be used more bigger like HIWIN45 AND HIWIN55.

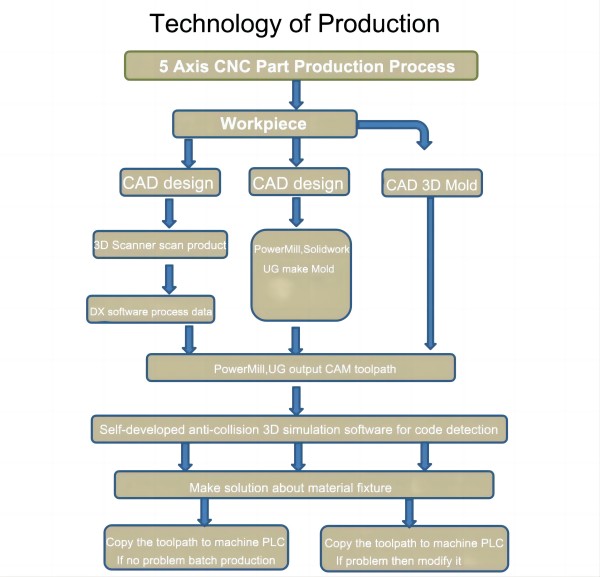

3. Technology of Production Assemble

This is a very important point, but it is also one that most people ignore. It is difficult for people to see differences in production processes from pictures.

The some very cheap 5 axis cnc router machines are all produced by small workshops, with two or three people working together in a production workshop. Here, they buy a gantry, and there, they buy a frame and assemble it themselves to sell. They have limited funds, and the technical workers are new recruits, which cannot guarantee accuracy. They also do not have their own designs, and they are all imitations of machines from large manufacturers. They do not understand mechanical principles, so the machines produced are prone to large errors also some issue which their technology cannot solve at all.

The regular large factory production process is firstly drawing customized by designer from their own workers then professional assembly workers, quality inspectors, service person, technical person and other departments work together to produce a reliable and stable 5-axis engraving machine.

As a professional 5 axis cnc router manufacturer the bed is welded by ourselves, then assembly by professional workers. After vibration aging, sandblasting, and spraying, there are no problems after completion. After installation and debugging, each workshop has a clear task work. Workshop 1 assembles, workshop 2 welds, and workshop 3 is our processing workshop so there are no problems with the parameters and modules in all aspects.

Also in machine structure technology is different from different suppliers. Like Rhino CNC company produce 5 axis cnc machine X axis are along with 3 pieces rails and Z axis are along with 4 pieces rails. Others factory usually X axis 2 pieces rails and Z axis 2 pieces rails so the machine cost go down some much !

Below show some photos:

4. Supplier Brand & Reputation

Low price machine usually from small company and the most professional large factory usually offer a reasonable price same time make sure quality and service both well . For 5 axis cnc milling center machine purchase the service and warranty both very important. Because machine are unpackaged as many parts before delivery and you have to install all by yourself (or supplier engineers) and PLC program with different toolpath training is necessary for different sculpture and molds.

The professional 5 axis cnc router machine supplier in China have some like RhinoCNC, CHENCAN CNC etc.

There are so many factors that affect the price of this 5 axis cnc machine, how can you choose a 5-axis cnc machine center that suits you?

1, It is necessary to determine the detail usage needs and scenarios, including the type of material to be processed, processing dimensions, operational difficulty, equipment movement or not etc., in order to have a targeted when selecting a 5 axis machine

2. Refer to some different machine brands and models, compare their performance, weight, price, and other comprehensive factors, and select the 5 axis machine that is suitable for yourself

3. Before purchasing, be sure to check the detailed parameters and usage instructions of 5 axis cnc router, understand its usage requirements and precautions;

4. Choose 5-axis machine brands with quality assurance and after-sales service as much as possible, and purchase from legitimate channels to obtain a better user experience.

Some economic and durable 5 axis cnc router recommended:

China 5 Axis CNC Machine Center with Syntec Control System Table Moving

Economic 5 Axis CNC Router for Foam EPS Wood Aluminum Mould Making

Professional 5 Axis CNC Router for Foam Mold Sculpture Car Mold Aluminum Mold Boat Mold making

Rhino DAMES 5 Axis CNC Router Woodworking for 3D Mold Sculpture Making

summary

This article introduces the relevant knowledge about 5 axis cnc router machine price cost , hoping to help everyone better understand and choose a suitable machine, thereby improving work efficiency and quality !

If you live this article welcome to visit our website : www.rhinocncmachine.com

Leave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG