By Serena Zhang | 21 November 2023 | 0 Comments

How to Mold EVA Foam Polystyrene by 5 Axis CNC Router (Small Size and Big Size Solution)

How to Mold EVA Foam Polystyrene by 5 Axis CNC Router

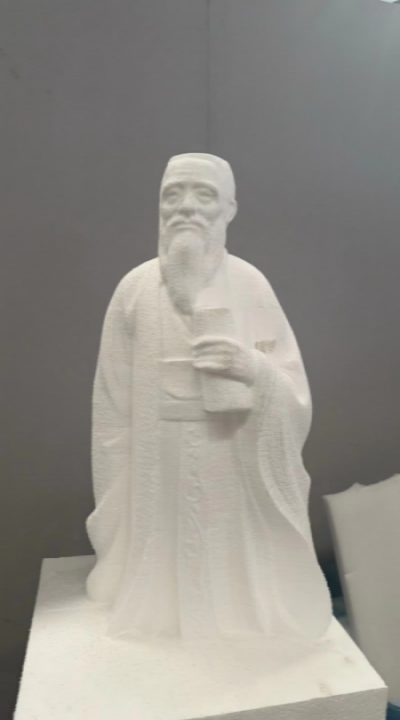

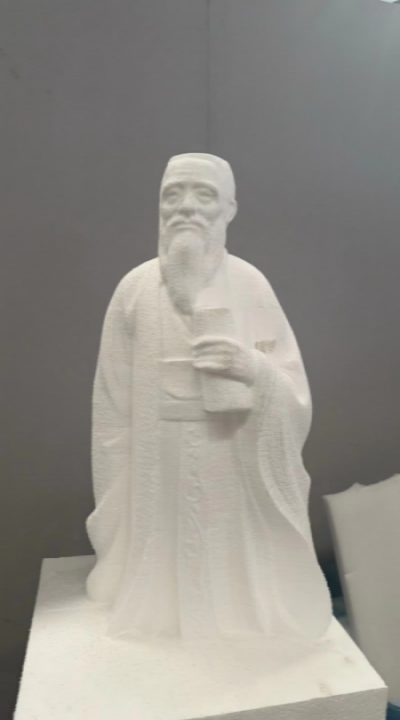

With the rapid development of the sculpture industry, EVA foam mold sculpture has gradually entered the ranks of diversified development.

Customization foam mold sculpture shows many characteristics. Its operability is very strong, and the operation is very convenient.

Therefore, foam sculpture has shown its unique charm in many fields. Its product weight is very low, the price is relatively low, the production time is very short also,

Therefore, it is highly popular among people now.

Foam model customization is now widely used in various exhibition venues.

Some outdoor advertisements also use this kind of model product, and this kind of sculpture product is used in the layout of some commercial spaces, some wedding scenes, and some large-scale shopping malls.

Its application range is very wide, This type of model has gradually been used to replace some original decorations, and the craftsmanship of this sculpture has made rapid progress, gradually meeting people's needs for use.

What is EVA ,FOAM and Polystyrene?

Foam has included: PVC,PS,,PE,PF,PUR,SAN,PEI,PMI,EVA etc.

For mold use usually need density bigger like more than 15-20kg/m2 then no problem.

If more smaller density the milling surface easy rough more.

How to mold on EVA Foam and Polystyrene perfectly?

Step 1: First, 5 axis cnc router machine to make the foam model

Step 2: spray polyurea soft PU by polyspray machine to protect foam from cracking

Step 3: Brush painting with different color you need

Step 4: Paint polyurethane topcoat on surface

Stepe 1, also the most improtant process:

Choose a proper 5 axis cnc router to make the mold on EVA foam and Polystyrene perfectly.

As per the foam dimension we have two types 5 axis cnc machine , one is table moving 5 axis cnc router, another is gantry moving 5 axis cnc router.

Table moving 5 axis cnc machine mainly process something small size foam like

800mmx600mm/1600mmx800mm/1300mmx1300mm and usually the table size is less 2000mm.

Here is machine photo with table moving single table+ double tables:

Single table moving 5 axis cnc center:

Table size 1300mmx1300mm/1300mmx1800mm/600mmx600mm/600mmx1800mm for option.

Professional for soft material and hard wood, aluminium and stone mold making .

DAMES L500 series 5 axis head

HQD 9KW water cooling 5 axis spindle

Syntec control system

Syntec servo motor drivers

RTCP function

Double table moving 5 axis cnc router

Two tables working one by one with size Table size

1300mmx1300mm/1300mmx1800mm/600mmx600mm/600mmx1800mm

Professional for soft material and hard wood, aluminium and stone mold milling and cutting.

DAMES L500 series 5 axis head

HQD 9KW water cooling 5 axis spindle

Syntec control system

Syntec servo motor drivers

RTCP function

Another for big size foam process like 2000mmx3000mm/2000mmx4000mm and more, there have gantry moving 5 axis cnc center to use:

2000mmx3000mm 5 axis cnc router for foam mold making RSKM25-T

This five axis engraving machine controls the swing angle of the five axis head through a CNC system to achieve five axis linkage machining. Some classic CNC systems include European OSA, which is a German CNC system comparable to Siemens

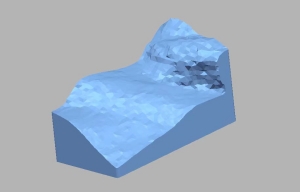

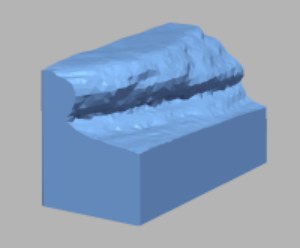

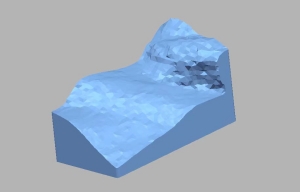

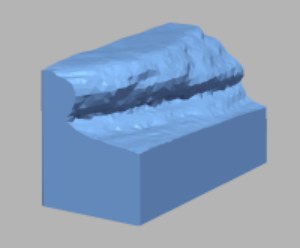

2000mmx8000mm 5 axis cnc router for boat,car and yacht mold making RSKM2080

Usually large size boat and yachat and cars moulds are made by this large size 5 axis cnc router with width 2000mm and length 8000mm.

Machine will cut and engrave on large block foam to make proper model as customer needs.

The reason for choosing the 5 axis cnc machining center is because of its professional processing capabilities. It has a multi axis control system, which can carry out accurate cutting and engraving operations in multiple directions, making the foam model produced with higher precision and complexity. By using the five axis machining center to make the yacht foam model, the designer's creativity and requirements can be realized, and the production efficiency and precision can be improved at the same time

Foam tools used in 5 axis cnc router

This ball nose tools is professional for foam mold milling and cutting with big discharge slot

Foam is material easy to process.

Foam engraving milling cutter can quickly cut and carve various shapes and patterns, so it is often used to make various models, such as building models, mechanical models, electronic product models, etc

It is used in mould making with length more than 200mm

Diameter 10mm/12mm/20mm

Step 2: spray polyurea soft PU by polyspray machine to protect foam from bursting

Polyurea is a new type of material that combines waterproofing and anti-corrosion effects with the application of new technologies, new materials, and new processes.

Its excellent anti-corrosion properties include no additives for dry solidification, fast molding, and the ability to easily spray coatings on building facades and curved surfaces without sagging, overcoming the complex construction and long molding time of the original anti-corrosion structural engineering.

Step 3: Brush painting with different color you need

Generally, colorful colors are used to better contrast the environment.

In order to make the color better, acrylic pigments are usually used for coloring. People can dilute this pigment with water, and the coloring method is usually to use a brush first.

The sculpture is first brushed with white latex, then naturally dried, and then layered with acrylic pigments.

If you want to use a spray gun for spraying, you can directly adjust the acrylic pigment with water, and then spray it directly onto the sculpture. After the pigment naturally dries, the sculpture can have a good waterproof effect and anti-aging effect.

Step 4: Paint polyurethane topcoat on surface

Polyurethane anti-corrosion paint is the most widely used coating in industrial anti-corrosion, and both polyurethane varnish and polyurethane topcoat belong to the topcoat series.

The biggest feature of polyurethane anti-corrosion paint is its high weather resistance, which can effectively maintain the luster and chromaticity of the paint film color.

Both polyurethane varnish and polyurethane topcoat have weather resistance

Now the model last step is painting the polyurethane topcoat on the smooth surface to keep a long time color and with light effect also.

Making a good foam model is not a easy work but also a great job to challenge.

No matter it is a small size model or a large size model basically need a good quality 5 axis cnc router to assist firstly and after that need all kinds of painting on surface of model.

Other related machine for foam model cutting:

CNC Hot wire cutting machine

This machine table size 1300mmx3000mm/4000mmx4000mm and other size can be customized also.

It work by hot wire heating to cut foam in different shapes.

We are professional cnc machine manufacturer and professional for different model moulds making.

Welcome to contact us if you have any questions for that and we would like to offer the good solution !

THE END !

With the rapid development of the sculpture industry, EVA foam mold sculpture has gradually entered the ranks of diversified development.

Customization foam mold sculpture shows many characteristics. Its operability is very strong, and the operation is very convenient.

Therefore, foam sculpture has shown its unique charm in many fields. Its product weight is very low, the price is relatively low, the production time is very short also,

Therefore, it is highly popular among people now.

Foam model customization is now widely used in various exhibition venues.

Some outdoor advertisements also use this kind of model product, and this kind of sculpture product is used in the layout of some commercial spaces, some wedding scenes, and some large-scale shopping malls.

Its application range is very wide, This type of model has gradually been used to replace some original decorations, and the craftsmanship of this sculpture has made rapid progress, gradually meeting people's needs for use.

What is EVA ,FOAM and Polystyrene?

Foam has included: PVC,PS,,PE,PF,PUR,SAN,PEI,PMI,EVA etc.

For mold use usually need density bigger like more than 15-20kg/m2 then no problem.

If more smaller density the milling surface easy rough more.

How to mold on EVA Foam and Polystyrene perfectly?

Step 1: First, 5 axis cnc router machine to make the foam model

Step 2: spray polyurea soft PU by polyspray machine to protect foam from cracking

Step 3: Brush painting with different color you need

Step 4: Paint polyurethane topcoat on surface

Stepe 1, also the most improtant process:

Choose a proper 5 axis cnc router to make the mold on EVA foam and Polystyrene perfectly.

As per the foam dimension we have two types 5 axis cnc machine , one is table moving 5 axis cnc router, another is gantry moving 5 axis cnc router.

Table moving 5 axis cnc machine mainly process something small size foam like

800mmx600mm/1600mmx800mm/1300mmx1300mm and usually the table size is less 2000mm.

Here is machine photo with table moving single table+ double tables:

Single table moving 5 axis cnc center:

Table size 1300mmx1300mm/1300mmx1800mm/600mmx600mm/600mmx1800mm for option.

Professional for soft material and hard wood, aluminium and stone mold making .

DAMES L500 series 5 axis head

HQD 9KW water cooling 5 axis spindle

Syntec control system

Syntec servo motor drivers

RTCP function

Double table moving 5 axis cnc router

Two tables working one by one with size Table size

1300mmx1300mm/1300mmx1800mm/600mmx600mm/600mmx1800mm

Professional for soft material and hard wood, aluminium and stone mold milling and cutting.

DAMES L500 series 5 axis head

HQD 9KW water cooling 5 axis spindle

Syntec control system

Syntec servo motor drivers

RTCP function

Another for big size foam process like 2000mmx3000mm/2000mmx4000mm and more, there have gantry moving 5 axis cnc center to use:

2000mmx3000mm 5 axis cnc router for foam mold making RSKM25-T

This five axis engraving machine controls the swing angle of the five axis head through a CNC system to achieve five axis linkage machining. Some classic CNC systems include European OSA, which is a German CNC system comparable to Siemens

2000mmx8000mm 5 axis cnc router for boat,car and yacht mold making RSKM2080

Usually large size boat and yachat and cars moulds are made by this large size 5 axis cnc router with width 2000mm and length 8000mm.

Machine will cut and engrave on large block foam to make proper model as customer needs.

The reason for choosing the 5 axis cnc machining center is because of its professional processing capabilities. It has a multi axis control system, which can carry out accurate cutting and engraving operations in multiple directions, making the foam model produced with higher precision and complexity. By using the five axis machining center to make the yacht foam model, the designer's creativity and requirements can be realized, and the production efficiency and precision can be improved at the same time

Foam tools used in 5 axis cnc router

This ball nose tools is professional for foam mold milling and cutting with big discharge slot

Foam is material easy to process.

Foam engraving milling cutter can quickly cut and carve various shapes and patterns, so it is often used to make various models, such as building models, mechanical models, electronic product models, etc

It is used in mould making with length more than 200mm

Diameter 10mm/12mm/20mm

Step 2: spray polyurea soft PU by polyspray machine to protect foam from bursting

Polyurea is a new type of material that combines waterproofing and anti-corrosion effects with the application of new technologies, new materials, and new processes.

Its excellent anti-corrosion properties include no additives for dry solidification, fast molding, and the ability to easily spray coatings on building facades and curved surfaces without sagging, overcoming the complex construction and long molding time of the original anti-corrosion structural engineering.

Step 3: Brush painting with different color you need

Generally, colorful colors are used to better contrast the environment.

In order to make the color better, acrylic pigments are usually used for coloring. People can dilute this pigment with water, and the coloring method is usually to use a brush first.

The sculpture is first brushed with white latex, then naturally dried, and then layered with acrylic pigments.

If you want to use a spray gun for spraying, you can directly adjust the acrylic pigment with water, and then spray it directly onto the sculpture. After the pigment naturally dries, the sculpture can have a good waterproof effect and anti-aging effect.

Step 4: Paint polyurethane topcoat on surface

Polyurethane anti-corrosion paint is the most widely used coating in industrial anti-corrosion, and both polyurethane varnish and polyurethane topcoat belong to the topcoat series.

The biggest feature of polyurethane anti-corrosion paint is its high weather resistance, which can effectively maintain the luster and chromaticity of the paint film color.

Both polyurethane varnish and polyurethane topcoat have weather resistance

Now the model last step is painting the polyurethane topcoat on the smooth surface to keep a long time color and with light effect also.

Making a good foam model is not a easy work but also a great job to challenge.

No matter it is a small size model or a large size model basically need a good quality 5 axis cnc router to assist firstly and after that need all kinds of painting on surface of model.

Other related machine for foam model cutting:

CNC Hot wire cutting machine

This machine table size 1300mmx3000mm/4000mmx4000mm and other size can be customized also.

It work by hot wire heating to cut foam in different shapes.

We are professional cnc machine manufacturer and professional for different model moulds making.

Welcome to contact us if you have any questions for that and we would like to offer the good solution !

THE END !

Leave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG