By Serena Zhang | 16 November 2023 | 1 Comments

How to Operate ATC CNC Machine - Buyer Guide

How to Operate ATC CNC Machine - Buyer Guide

In recent years, ATC CNC Machine has been favored by many people. Several years before the ordinary 3 axis cnc router without automatic tool changer was popular, now because of great development of social economy and technological progress ,the ATC CNC Router machine has replaced the common 3 axis cnc router well.

But more and more customers who get the ATC CNC machine they do not know how to operate this machine well. They don't understand the principle and configuration of ATC CNC machine, which will lead to improper operation. These small mistake may affect the machine working performance and you may think it is quality problem.

Today, we will introduce to you how to use & operate the ATC CNC Machine well.

What is most necessary 3 steps before start ATC CNC Machine working?

1. Inspect machine XYZ movement properly or not and inspect XYZ limit sensor work well or not

2. Operate XYZ all axis go home point smoothly

3. Learn the most commonly used bottons in Syntec system and check spindle clamp & unclamp tools function

1. Inspect machine XYZ movement properly or not and inspect XYZ limit sensor work well or not

When first time turn on machine, no need to let all axis go home point. The necessary inspect step we suggest is move X/Y/Z axis and check them move smoothly or not. This action is done by handle wheel and same time check all limit sensor work well or not. The detail operation please check below video:

https://youtu.be/J9pTlIlVCq8

2. Operate XYZ all axis go home point smoothly

After make sure all axis movement smooth and limit sensor no problem ,next we can operate x/y/z go home point, there have two ways one is go home point manually and another is go home point automatically. Details welcome to check below video:

https://www.youtube.com/shorts/H-7l9HUU2a0?feature=share

3. Learn the most commonly used bottons in Syntec system and check spindle clamp & unclamp tools function

After make sure all axis go machine home piint well, means the movment and program no any problem. Next step we should learn ATC CNC Machine operation system -Syntec 60WE and same time check spindle clamp& unclamp function.

The most frequently used buttons in syntec system:

JOG - Manual mode

HOME- Go home point mode

MPG- Handle wheel mode

MDI - Edit mode

AUTO - Auto working mode

After you know them well then can operate machine more easily.

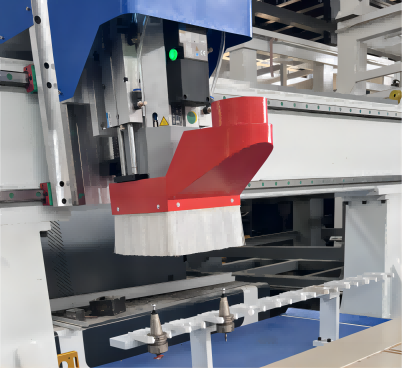

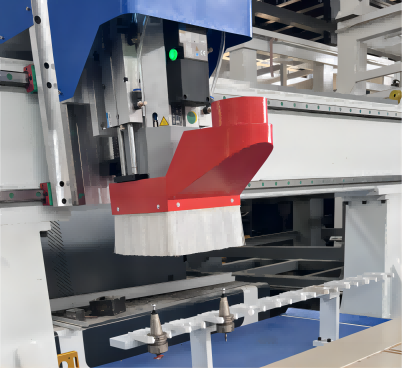

Next step check the ATC CNC spindle clamp and unclamp function well or not.

On spindle there have a green button, you need press it and the tools will be loosed,same way check the tools can be clamped by spindle or not.

Here is the operation video for your reference:

https://www.youtube.com/shorts/F-VC_YV-A_U?feature=share

After inspect well for above 3 steps, next we will go to set something about tools:

1. How to set Tool position automatically ?

2. How to set Tool length automatically ?

1. How to set Tool position automatically

Before this ATC CNC machine delivery our engineer already seted all tools position well , but in long time transportation the tool magazine location maybe a little changed,so we advise you set every tool location(position)again one by one to get the best accurate location.

The detail operation video kindly check below:

https://youtu.be/ZfrF05Pt_tM

2. How to set Tool length automatically

Different tools length is different also in every tool holder,so before machine start working you need set different tools length and input syntec program. This action can be done with the auto tool sensor. Every tool get length on tool sensor 3 times to get the exact data. The detail operation video please check below:

https://youtu.be/kAJjcMvZHcI

After you did all inspection and setting in ATC CNC machine and Syntec program, then finally we can start machine working. Just input the G-code into Syntec USB interfact and ATC CNC machine will work it perfectly.

Related knowledge:

1.What is ATC in CNC Machine?

2. What is program in ATC CNC Router machine -Syntec 60WE?

1.What is ATC in CNC Machine?

Automatic tool changer, referred to as ATC, is a device on CNC machine that tools can be automatically changed, improve equipment productivity and increase the number of supported tools. The automatic tool changer can quickly change the tools on the machine tool and reduce non-running time. Automatic tool changers are generally designed to improve the capabilities of machine tools and can be used with a variety of tools. The automatic tool changer can also be used to replace worn or damaged tools. It can take machine tools one step closer to the goal of automation

The advantages of ATC in CNC Machine:

1. Improve production efficiency: Due to the use of automated tool changing systems, manual intervention time is reduced, thereby improving production efficiency. This is very beneficial for both high-volume production and low-volume customization production environments.

2. Reduce human errors: Human errors are prone to occur during manual tool changing, such as incorrectly cutting workpieces, tool damage, etc. Automated tool changing systems can avoid these problems because they operate based on preset programs.

3. Higher machining accuracy: Because the automated tool changing system can accurately position and replace tools, higher machining accuracy can be achieved. This is particularly important for applications that require high-precision machining (such as aviation, aerospace, precision mold manufacturing, etc.).

4. Extend tool life: The automated tool changing system can adjust cutting parameters in real time according to the actual use of the tool, thereby extending the tool life.

5. Save maintenance time and costs: The automatic tool changing system can reduce the need for inspection and maintenance of the spindle and tools, thereby saving maintenance time and costs.

Original link: WIKIPEDIA

2. What is program in ATC CNC Router machine -Syntec 60WE?

Syntec 60WE is made from Taiwan China that very popular used in cnc router machine 3 axis, 4 axis and 5 axis.

CNC machine tools are digitally simulated through computer and display on Syntec screen. Through the simulator, we can experience the operations of real machine tools on the computer, such as blank definition, reference tool setting, edge finder tool setting, tool installation, machine tool processing programming and manual operation, etc., which can help Machine tool staff quickly familiarize themselves with and master the use of new generation machine tools.

Recommended ATC CNC Machine:

CNC Router Machine with ATC Funtion

and Extra Drilling Head

Linear Tool Magazine CNC Router Australia

with ATC Function for Woodworking

4 Axis 2040 ATC CNC Router with Rotary & Linear Tool Changer

4x8ft CNC Router with ATC Funtion for Sale

In recent years, ATC CNC Machine has been favored by many people. Several years before the ordinary 3 axis cnc router without automatic tool changer was popular, now because of great development of social economy and technological progress ,the ATC CNC Router machine has replaced the common 3 axis cnc router well.

But more and more customers who get the ATC CNC machine they do not know how to operate this machine well. They don't understand the principle and configuration of ATC CNC machine, which will lead to improper operation. These small mistake may affect the machine working performance and you may think it is quality problem.

Today, we will introduce to you how to use & operate the ATC CNC Machine well.

What is most necessary 3 steps before start ATC CNC Machine working?

1. Inspect machine XYZ movement properly or not and inspect XYZ limit sensor work well or not

2. Operate XYZ all axis go home point smoothly

3. Learn the most commonly used bottons in Syntec system and check spindle clamp & unclamp tools function

1. Inspect machine XYZ movement properly or not and inspect XYZ limit sensor work well or not

When first time turn on machine, no need to let all axis go home point. The necessary inspect step we suggest is move X/Y/Z axis and check them move smoothly or not. This action is done by handle wheel and same time check all limit sensor work well or not. The detail operation please check below video:

https://youtu.be/J9pTlIlVCq8

2. Operate XYZ all axis go home point smoothly

After make sure all axis movement smooth and limit sensor no problem ,next we can operate x/y/z go home point, there have two ways one is go home point manually and another is go home point automatically. Details welcome to check below video:

https://www.youtube.com/shorts/H-7l9HUU2a0?feature=share

3. Learn the most commonly used bottons in Syntec system and check spindle clamp & unclamp tools function

After make sure all axis go machine home piint well, means the movment and program no any problem. Next step we should learn ATC CNC Machine operation system -Syntec 60WE and same time check spindle clamp& unclamp function.

The most frequently used buttons in syntec system:

JOG - Manual mode

HOME- Go home point mode

MPG- Handle wheel mode

MDI - Edit mode

AUTO - Auto working mode

After you know them well then can operate machine more easily.

Next step check the ATC CNC spindle clamp and unclamp function well or not.

On spindle there have a green button, you need press it and the tools will be loosed,same way check the tools can be clamped by spindle or not.

Here is the operation video for your reference:

https://www.youtube.com/shorts/F-VC_YV-A_U?feature=share

After inspect well for above 3 steps, next we will go to set something about tools:

1. How to set Tool position automatically ?

2. How to set Tool length automatically ?

1. How to set Tool position automatically

Before this ATC CNC machine delivery our engineer already seted all tools position well , but in long time transportation the tool magazine location maybe a little changed,so we advise you set every tool location(position)again one by one to get the best accurate location.

The detail operation video kindly check below:

https://youtu.be/ZfrF05Pt_tM

2. How to set Tool length automatically

Different tools length is different also in every tool holder,so before machine start working you need set different tools length and input syntec program. This action can be done with the auto tool sensor. Every tool get length on tool sensor 3 times to get the exact data. The detail operation video please check below:

https://youtu.be/kAJjcMvZHcI

After you did all inspection and setting in ATC CNC machine and Syntec program, then finally we can start machine working. Just input the G-code into Syntec USB interfact and ATC CNC machine will work it perfectly.

Related knowledge:

1.What is ATC in CNC Machine?

2. What is program in ATC CNC Router machine -Syntec 60WE?

1.What is ATC in CNC Machine?

Automatic tool changer, referred to as ATC, is a device on CNC machine that tools can be automatically changed, improve equipment productivity and increase the number of supported tools. The automatic tool changer can quickly change the tools on the machine tool and reduce non-running time. Automatic tool changers are generally designed to improve the capabilities of machine tools and can be used with a variety of tools. The automatic tool changer can also be used to replace worn or damaged tools. It can take machine tools one step closer to the goal of automation

The advantages of ATC in CNC Machine:

1. Improve production efficiency: Due to the use of automated tool changing systems, manual intervention time is reduced, thereby improving production efficiency. This is very beneficial for both high-volume production and low-volume customization production environments.

2. Reduce human errors: Human errors are prone to occur during manual tool changing, such as incorrectly cutting workpieces, tool damage, etc. Automated tool changing systems can avoid these problems because they operate based on preset programs.

3. Higher machining accuracy: Because the automated tool changing system can accurately position and replace tools, higher machining accuracy can be achieved. This is particularly important for applications that require high-precision machining (such as aviation, aerospace, precision mold manufacturing, etc.).

4. Extend tool life: The automated tool changing system can adjust cutting parameters in real time according to the actual use of the tool, thereby extending the tool life.

5. Save maintenance time and costs: The automatic tool changing system can reduce the need for inspection and maintenance of the spindle and tools, thereby saving maintenance time and costs.

Original link: WIKIPEDIA

2. What is program in ATC CNC Router machine -Syntec 60WE?

Syntec 60WE is made from Taiwan China that very popular used in cnc router machine 3 axis, 4 axis and 5 axis.

CNC machine tools are digitally simulated through computer and display on Syntec screen. Through the simulator, we can experience the operations of real machine tools on the computer, such as blank definition, reference tool setting, edge finder tool setting, tool installation, machine tool processing programming and manual operation, etc., which can help Machine tool staff quickly familiarize themselves with and master the use of new generation machine tools.

Recommended ATC CNC Machine:

CNC Router Machine with ATC Funtion

and Extra Drilling Head

Linear Tool Magazine CNC Router Australia

with ATC Function for Woodworking

4 Axis 2040 ATC CNC Router with Rotary & Linear Tool Changer

4x8ft CNC Router with ATC Funtion for Sale

Recently Reviews

Read MoreLeave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG