By Serena zhang | 19 January 2024 | 0 Comments

What is a 5 Axis CNC Machine ?

What is A 5 Axis CNC Machine ?

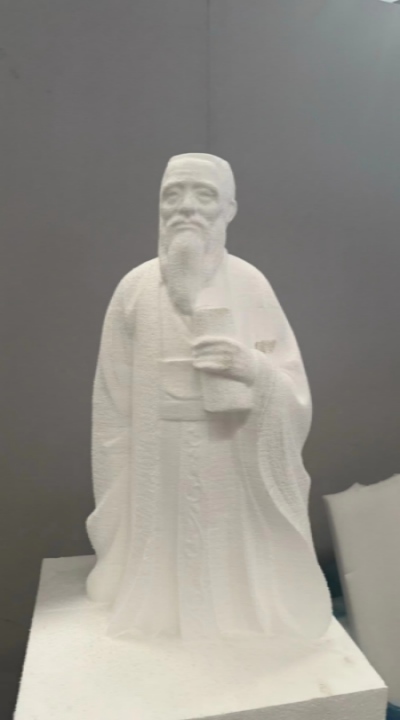

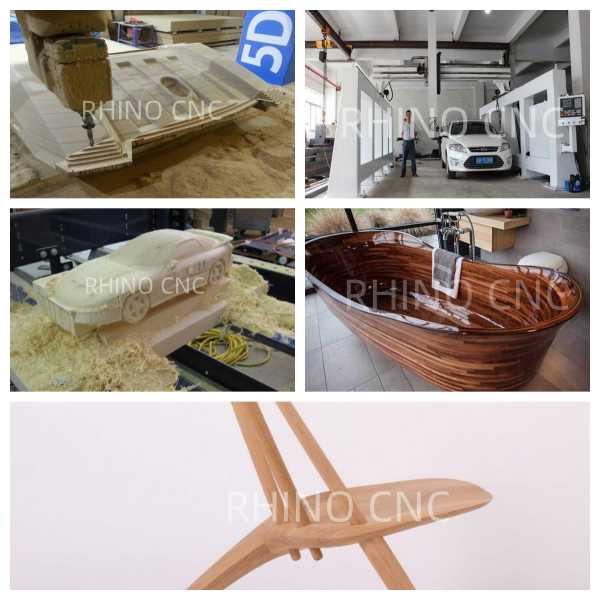

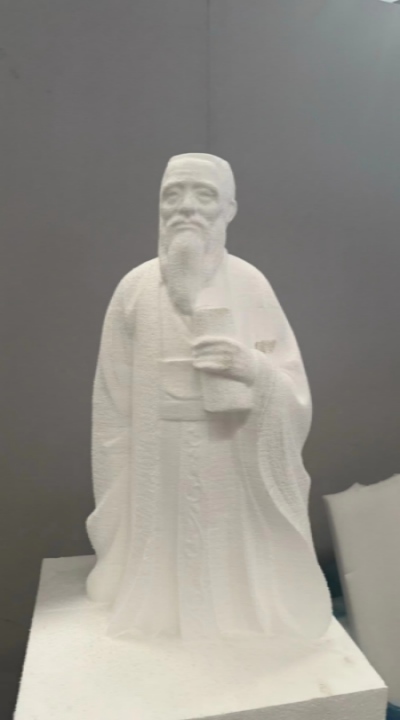

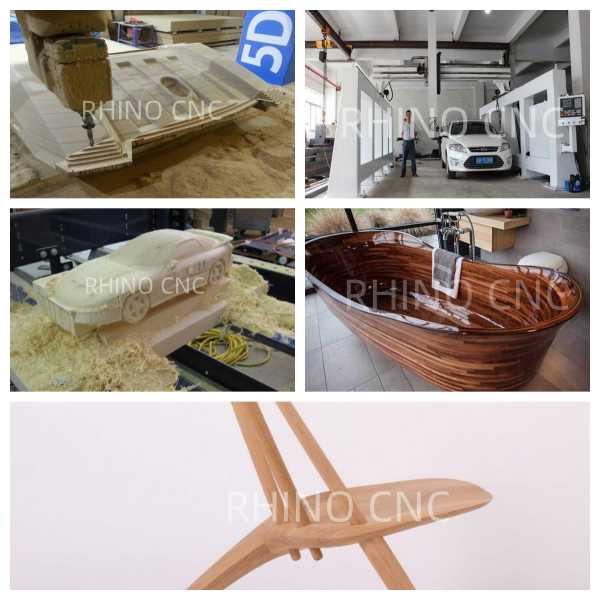

Today we are talking about the 5 axis cnc machine is not for the metal cnc lathe especially for metal high precision milling. We are talking the 5 axis cnc router mostly for 3D 4D 5D models figurine sculptures making with diverse materials like wood,stone,aluminum foam, EVA etc.

Before understanding 5 axis CNC machine, you’ll have to understand the ordinary cnc router 2 axis,3 axis and 4 axis.

A 2 axis CNC machining system has the ability to modify objects on a plane. This plane has only two coordinate systems, the x and the y axis.

Objects can be moved on a plane. If the plane is upright then an object can be modified top to bottom and left and right or forward and backward.

On a 3 axis CNC machine, (this is the most popular in market and everyone can afford it) an object can be modified in space. It can be modified, left and right, top to bottom, and forward and back. You may be wondering, isn’t a 3 axis CNC machine enough to handle any given object.

Since it can modify an object in space then it must be able to transform an object at any given point. All this is correct but there is still a need for 5 axis CNC machining. Why?

On a 4 axis cnc router, it has many definitions. The ordinary 3 axis cnc with rotary can be regard 4 axis cnc router. The ordinary 3 axis cnc router with spindle rotate 0-90 degree left and right also can be regard 4 axis cnc. So it means based on 3 axis then add a customized forth axis no matter it is rotary or other actions.

On a 2 axis CNC machine, you can modify objects in a plane. On a 3 axis CNC machine, you can modify objects in space. On a 4, 5, 6, and so on and so forth axis CNC machine, you’ll be able to modify an object on several axes. Modifying an object on the x, y, and z planes may not be enough to create a perfect sphere or a mold.

Maybe a 45 degree angle axis will help in smooth out the sphere and mold. Going further an opposite 45 degree angle axis may also help do the job and so on and so forth.

The more axes on a CNC machine translates into a more complex piece of equipment. For 5 axis CNC machining equipment, you can take advantage of the extra two axes aside from the x, y, and z planes. If you are making a piece of art, you can rotate the object in two more ways than the usual x, y, and z movements.

The extra axes may be a circular axis, a diagonal axis, or whatever. As long as the extra axes help in the production of the final product, you can always have a 5 axis CNC machining tool handy.

The 5 axis cnc machine is not simple 3+2 axis.

The extra axes on a 5 axis machine are commonly called the A and the B axis. The A axis is normally associated with the rotation of the product whilst the B axis is associated with the tilting of the product. This is the nomenclature that is used in many 5 axis machines but it can always vary from machine to machine.

It is not a easy task to achieve five axis working on one same point together. But recently this technical issue has been resolved. It is called RTCP function that mostly machine program have it like Taiwan Syntec, Siemens,OSAI etc.

If you are having a hard time picturing what 5 axis CNC machining is all about then think of an airplane. Imagine the number of ways it can move in the air. First, think about the plane moving forward in the forward-backward plane.

This is the first movement and your first axis. Second, think about the plane going up and down in the altitude plane. This is the second movement and your second axis. Third, think about the plane turning left and turning right. This is the third movement and your third axis. Here comes the tricky part. Now you have to imagine the plane rolling like a barrel. This is the fourth movement and your fourth axis. When a plane rolls from being upright to being upside down, its axis is entirely different from the other three.

The fifth movement is even trickier. When a plane lands, imagine the nose tilting upward but not increasing in altitude. This is the fifth movement and it is your fifth axis. The 5 axis CNC machining equipment can modify an object in the same manner that the plane moves around space.

Also the 5 axis cnc machining structure have many kinds and can be customized.

Like working table size 1300mmx2500mm,1500mmx3000mm,2000mmx3000mm,3000mm,6000mm etc.

The feeding height z axis usually 1000mm-2000mm

Like table moving 5 axis cnc machine, gantry movement cnc machining, ball screw 5 axis cnc machine,4 tools 5 axis cnc machine etc.

Below recommend some popular Rhino 5 axis cnc machine :

4 tools 5 axis cnc machining for woodworking RSKM25-HA

5D Aircraft Cars Mold Making CNC Machining RSKM25-T

Wooden Foundry Mold 5 Axis CNC Machine RSKM25-H

Table Moving 5 Axis CNC Machining RSKM25-HC

Gallery made by 5 Axis CNC Machining :

With 5 axis CNC machining technology, you can make objects like you’ve never expected.

More information if you have interest welcome to contact us or visit Youtube:

https://www.youtube.com/@RhinoCNC

Today we are talking about the 5 axis cnc machine is not for the metal cnc lathe especially for metal high precision milling. We are talking the 5 axis cnc router mostly for 3D 4D 5D models figurine sculptures making with diverse materials like wood,stone,aluminum foam, EVA etc.

Before understanding 5 axis CNC machine, you’ll have to understand the ordinary cnc router 2 axis,3 axis and 4 axis.

A 2 axis CNC machining system has the ability to modify objects on a plane. This plane has only two coordinate systems, the x and the y axis.

Objects can be moved on a plane. If the plane is upright then an object can be modified top to bottom and left and right or forward and backward.

On a 3 axis CNC machine, (this is the most popular in market and everyone can afford it) an object can be modified in space. It can be modified, left and right, top to bottom, and forward and back. You may be wondering, isn’t a 3 axis CNC machine enough to handle any given object.

Since it can modify an object in space then it must be able to transform an object at any given point. All this is correct but there is still a need for 5 axis CNC machining. Why?

On a 4 axis cnc router, it has many definitions. The ordinary 3 axis cnc with rotary can be regard 4 axis cnc router. The ordinary 3 axis cnc router with spindle rotate 0-90 degree left and right also can be regard 4 axis cnc. So it means based on 3 axis then add a customized forth axis no matter it is rotary or other actions.

On a 2 axis CNC machine, you can modify objects in a plane. On a 3 axis CNC machine, you can modify objects in space. On a 4, 5, 6, and so on and so forth axis CNC machine, you’ll be able to modify an object on several axes. Modifying an object on the x, y, and z planes may not be enough to create a perfect sphere or a mold.

Maybe a 45 degree angle axis will help in smooth out the sphere and mold. Going further an opposite 45 degree angle axis may also help do the job and so on and so forth.

The more axes on a CNC machine translates into a more complex piece of equipment. For 5 axis CNC machining equipment, you can take advantage of the extra two axes aside from the x, y, and z planes. If you are making a piece of art, you can rotate the object in two more ways than the usual x, y, and z movements.

The extra axes may be a circular axis, a diagonal axis, or whatever. As long as the extra axes help in the production of the final product, you can always have a 5 axis CNC machining tool handy.

The 5 axis cnc machine is not simple 3+2 axis.

The extra axes on a 5 axis machine are commonly called the A and the B axis. The A axis is normally associated with the rotation of the product whilst the B axis is associated with the tilting of the product. This is the nomenclature that is used in many 5 axis machines but it can always vary from machine to machine.

It is not a easy task to achieve five axis working on one same point together. But recently this technical issue has been resolved. It is called RTCP function that mostly machine program have it like Taiwan Syntec, Siemens,OSAI etc.

If you are having a hard time picturing what 5 axis CNC machining is all about then think of an airplane. Imagine the number of ways it can move in the air. First, think about the plane moving forward in the forward-backward plane.

This is the first movement and your first axis. Second, think about the plane going up and down in the altitude plane. This is the second movement and your second axis. Third, think about the plane turning left and turning right. This is the third movement and your third axis. Here comes the tricky part. Now you have to imagine the plane rolling like a barrel. This is the fourth movement and your fourth axis. When a plane rolls from being upright to being upside down, its axis is entirely different from the other three.

The fifth movement is even trickier. When a plane lands, imagine the nose tilting upward but not increasing in altitude. This is the fifth movement and it is your fifth axis. The 5 axis CNC machining equipment can modify an object in the same manner that the plane moves around space.

Also the 5 axis cnc machining structure have many kinds and can be customized.

Like working table size 1300mmx2500mm,1500mmx3000mm,2000mmx3000mm,3000mm,6000mm etc.

The feeding height z axis usually 1000mm-2000mm

Like table moving 5 axis cnc machine, gantry movement cnc machining, ball screw 5 axis cnc machine,4 tools 5 axis cnc machine etc.

Below recommend some popular Rhino 5 axis cnc machine :

4 tools 5 axis cnc machining for woodworking RSKM25-HA

5D Aircraft Cars Mold Making CNC Machining RSKM25-T

Wooden Foundry Mold 5 Axis CNC Machine RSKM25-H

Table Moving 5 Axis CNC Machining RSKM25-HC

Gallery made by 5 Axis CNC Machining :

With 5 axis CNC machining technology, you can make objects like you’ve never expected.

More information if you have interest welcome to contact us or visit Youtube:

https://www.youtube.com/@RhinoCNC

Leave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG